I think...LOL

I think...LOL

Last edited by Mark Norman; 03-24-2009 at 2:58 AM.

Mark, You are committed now and it should be a great feeling when it is all completed. I just ordered parts for my CNC router table so I know how you are feeling!! I can't wait to get it up and running just like you! Good luck and we are all waiting for the grand unveiling!

Have a great day!!

Jeff

To turn or not to turn that is the question: ........Of course the answer is...........TURN ,TURN,TURN!!!!

Anyone "Fool" can know, The important thing is to Understand................Albert Einstein

To follow blindly, is to never become a leader............................................ .....Unknown

I just read through this thread..What a cool project!

I think that you have a good plan here.

Don't rush the job. Working out the bugs can be the most exciting aspect of a project. I think that the devil's in the details.

I'm looking forward to the results.

Boy am I ever Jeff LOL,

Just today I bought a new 2 HP 3 phase motor ($250.00) and the VFD (another $250.00) and the spindle pulley (at cost for $83.50).

As soon as I get the face plate in hand I'll visit the machine shop again and get the spindle made up.

I stopped by the home improvement center today to determine the best material to use for the form work and concrete embed anchors. I'm putting the form work together in my head and I have some ideas I really like that I'll save for later

Thanks Steve,Originally Posted by Steve Frederick

I appreciate the encouragement.

It is turning out to be a real fun project. The research here is paying off, it helps to have input from others that are familiar with what I am working on.

The devil don't hold a candle to meand I will be posting more as I progress...The trials and the tribulations.....

Mark

Mark, what kind of VFD did you buy? If it is a Hitachi, I like to share some programming war stories with on the Vicmarc build I just completed.

This one Dave:

http://dealerselectric.com/item.asp?cID=&PID=400

I have a friend that programs these things all day long to help me out with any issues I might come across.

I plan on casting in a recess on the lathe just below the headstock to fit the remote control panel and I haven't decided if I will mount the VFD on the back by the motor or on a wall near-by.

Here is the headstock pulley I picked up today for about half of what a sheave and bushing would cost me. It only has a 1" center so I will have the machinist cut the spindle down to accept it and have 1"x8tpi cut on the outboard side and use a thread adapter for the faceplate.

The new Baldor motor is in the box behind it and I have a four step pulley to fit it on order and should be here in just a couple days.

I'll be able to turn at 50 to 500 rpm all day long. And I will have provisions to add a jack-shaft set up so I could spin at 3000 rpm

Last edited by Mark Norman; 03-24-2009 at 10:33 PM.

Mark,

It is sounding good so far.

If it were my project, I would have my machinist enlarge the hole in the pulley/sheave to 1 1/4" instead of cutting down the headstock shaft to 1". It looks like there is plenty of metal to enlarge the hole and have it still be plenty strong.

With the VFD, I'd mount it separate from the lathe. Electronics can be very sensitive to vibration. It also keeps the VFD away from most of the dust/shavings. I know that many manufacturers mount them on the lathe but I think separate is the best practice.

Good luck,

Dick

I agree the VF drive should be mounted seperate from the machine.

I'll talk to the machinist about the best way to join the spindle to the pulley.

Mark - any chance for pics of the purchased parts?

We're all behind you on the project!

Just the big head stock pulley and bearing so far. I'll open up the box with the motor in it as soon as I get the vfd and step pulley for it.

And you can bet I will post pics of the spindle when I get it done. give me a week or two for that.

I went shopping for materials today for the formwork and talked with a metal fabricator extraordinaire about building a steel form so I can reproduce the machine...

More to come.....got me some engineering to do....

I have that same henry taylor gouge and it's great. Looks like everything is coming along quite well. Are you getting enough sleep or is this keeping you up at night like buying a new lathe kept me up?

I sleep well Alex, Thanks for the concernI am getting anxious though. I am suitably impressed with the gouge and scraper I got yesterday. Quality stuff for sure.

I'm just waiting for a couple more parts to really get moving with the build.

Yeah I am a lil excited about it.

and made sure it fit on the motor today...

Got a cell phone pic of the pieces just for fun:

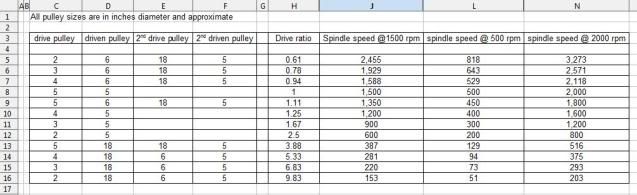

Doing some engineering on the motor vs headstock speeds using a jackshaft and I think I have it all worked out. I decided I didnt like the big pulley being on the headstock spinning way up high like that so I decided to add a jackshaft down lower on the machine and in doing so I have come up with twelve speed ratios possible. Likely I will only use a half a dozen at the most but it gives me plenty of options. I'll scan my sketch if anyone is interested..

Last edited by Mark Norman; 03-27-2009 at 9:46 PM.

I'm thinking I could add a 1" jackshaft in the outboard upright end of the machine with a 6 and 18" pulley, I could mount the motor up high so I could run it without the jackshaft most of the time. And for the occasion I want to turn a real large piece I could add the extra pulleys for real slow speed turning.

Dont laugh but feel free to comment

Someone please check my math.. I was soo confused after staring at it for a couple hours last night..:crazy: