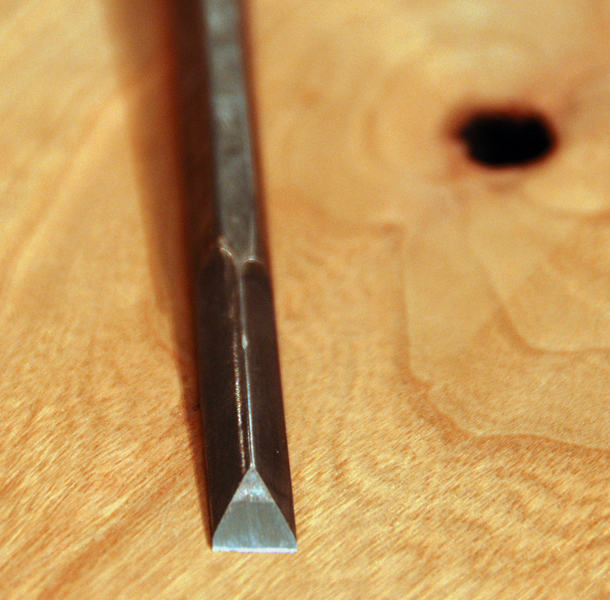

I just received my two cherries 1/2" chisel in the mail today! I am wondering something though, is there a way to grind off the sides so it is more of a triangle shape but with a flat part on top to help with sharpening it? The reason being for chopping out the waste in dovetails, so it won't leave that small 1/8" or so square part on the corners. And if this is do-able, would it just be done by eye, or is there some kind of jig to use to hold it right? Thanks for any help!

Reply With Quote

Reply With Quote

... but it works like a charm, don't know why i never thought to do this before

... but it works like a charm, don't know why i never thought to do this before