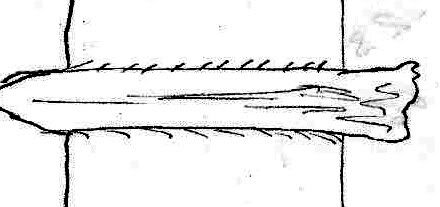

To amplify a bit on Jr's comments, it doesn't matter if the dowels are perfectly straight or smooth. The benefit of using a dowel plate is that the dowels follow the grain. In turned dowels there is almost always grain run-out which makes the dowels significantly weaker but potentially straighter.

Grain run-out, particularly when drawboring, is potentially disastrous.

"History is strewn with the wrecks of nations which have gained a little progressiveness at the cost of a great deal of hard manliness, and have thus prepared themselves for destruction as soon as the movements of the world gave a chance for it." -Walter Bagehot

Reply With Quote

Reply With Quote

Jr.

Jr.