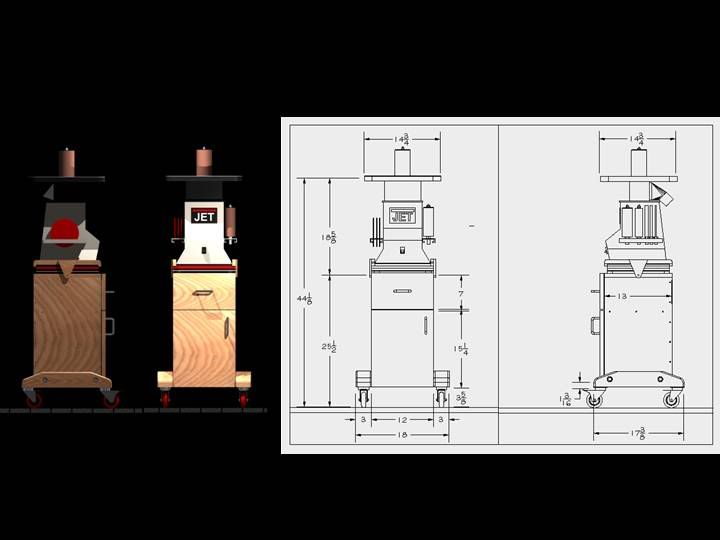

To all fellow Woodnics, I have a Jet bench top spindle sander and am considering building a dedicated mobile base so that I can finally get the thing at a comfortable working height. So, I am interested in knowing what designs you have come up with. A wise man (Dad) told me once it's better to work smart and hard than just hard. With that in mind I would like to see what the best of the best have designed. AL RIGHT ENOUGH BUTT KISSING - I just don't want to have to build this thing twice because I didn't consider some design element that would make the unit much more user friendly. Any help would be greatly appreciated.

Reply With Quote

Reply With Quote