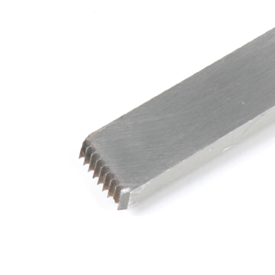

Here is a photo of 3 'fingernail tools' that I use for beads and stuff. They are just flat on top.The small one is 1/4" M3 that I got 20 years ago. I use it for my tops ad stoppers and little details. The next size is 1/2" that I made out of a captured ring tool I never used. This is one of the 4 tools I use most everyday. The big one is 3/4" and is under development as far as the shape goes. I was made from a Sorby scraper. You can see me using the medium one in a couple of my videos.

Reply With Quote

Reply With Quote