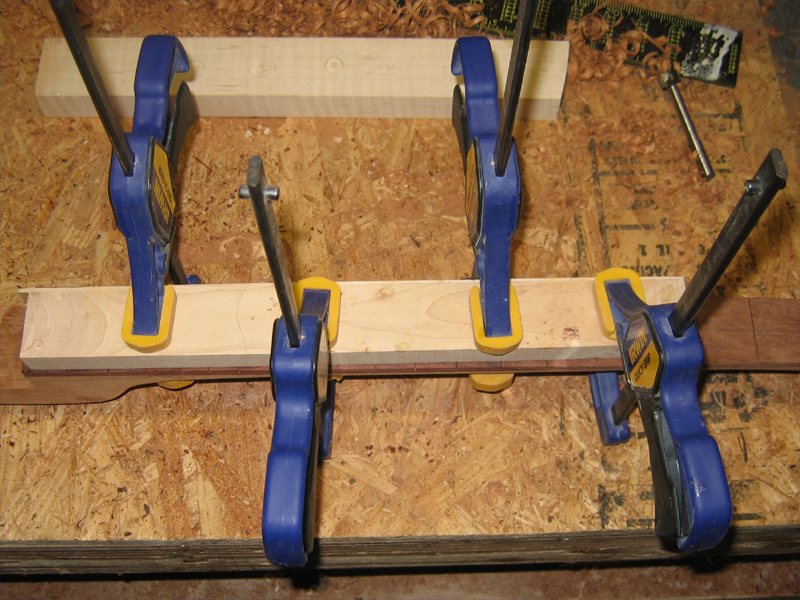

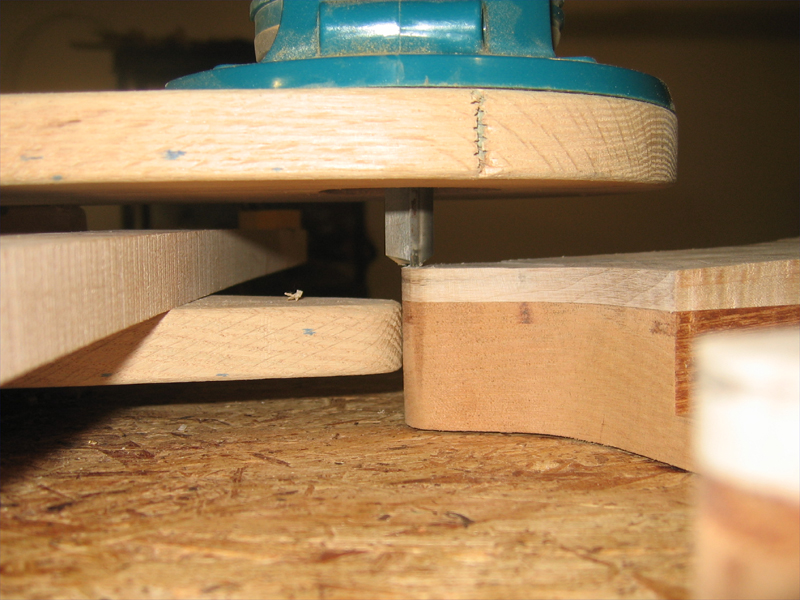

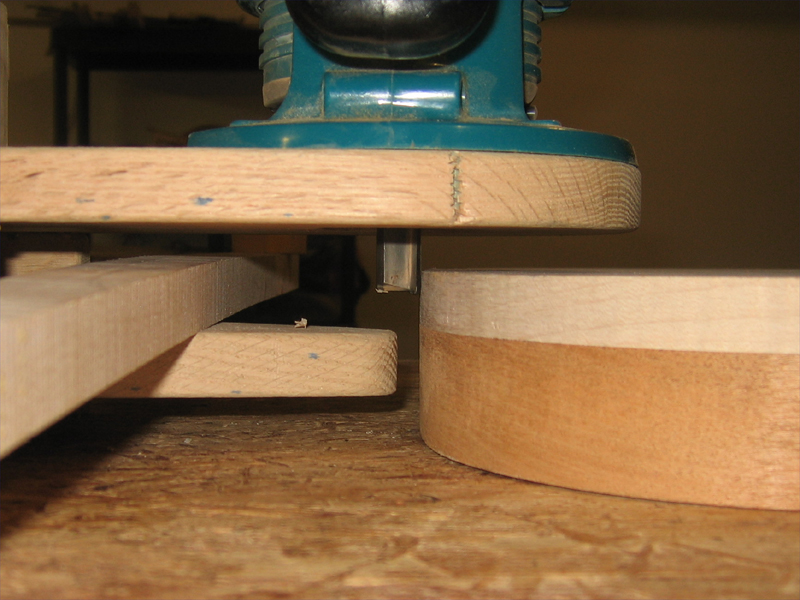

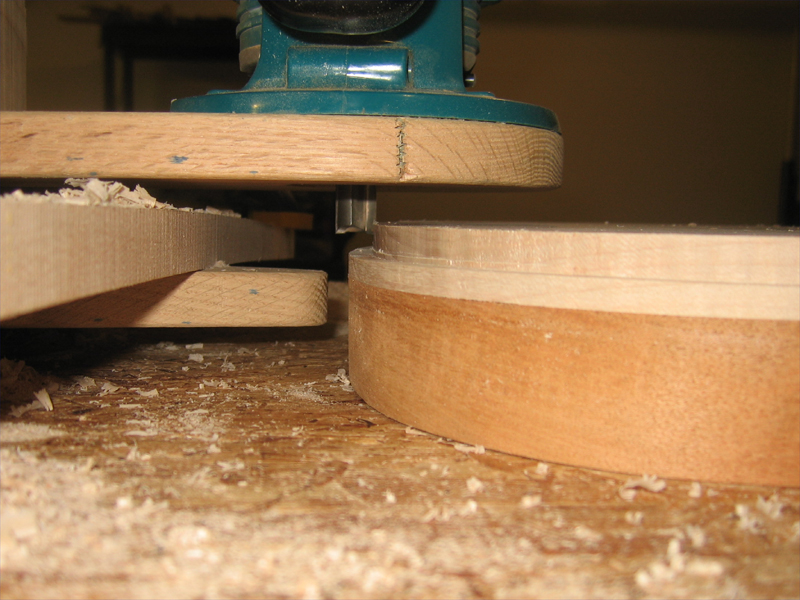

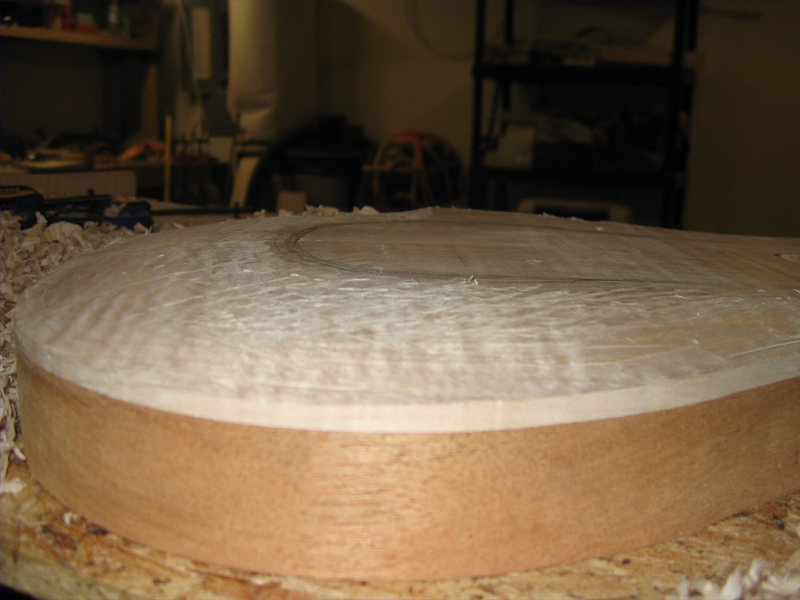

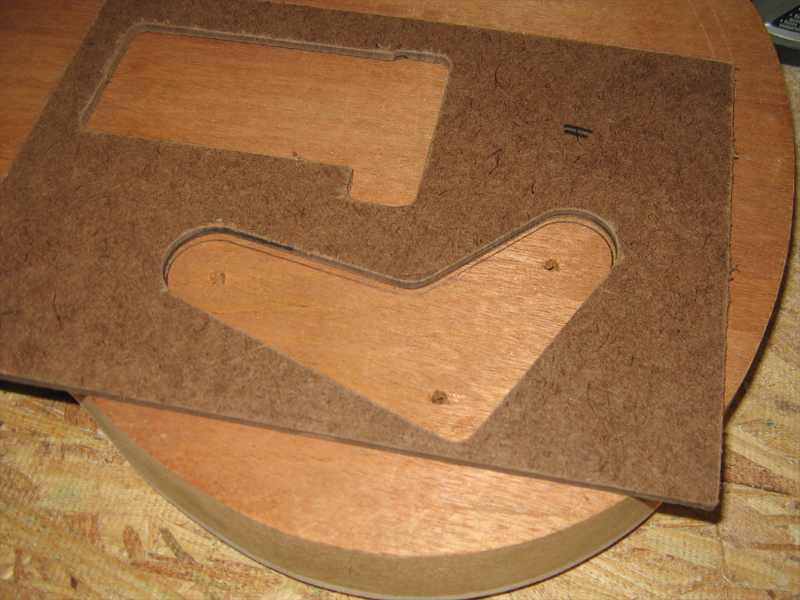

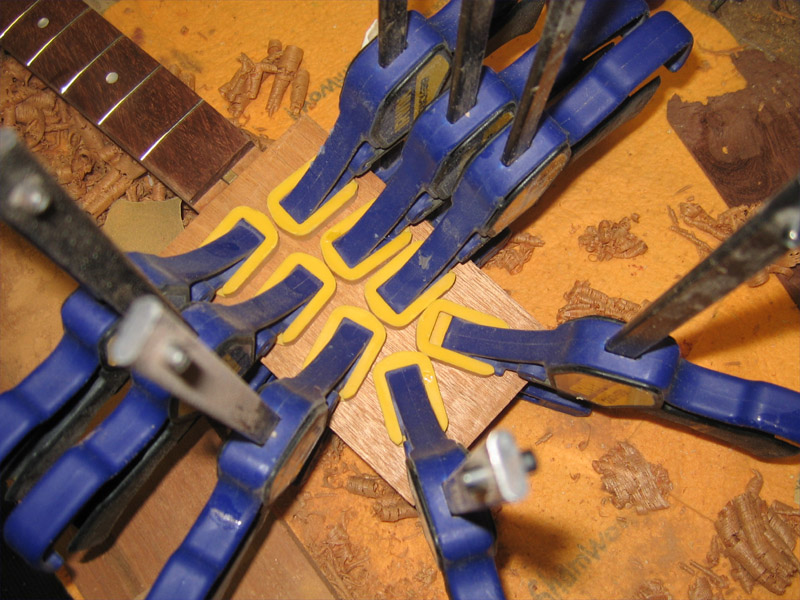

Still lots of work to do on the body but it's shaping up.

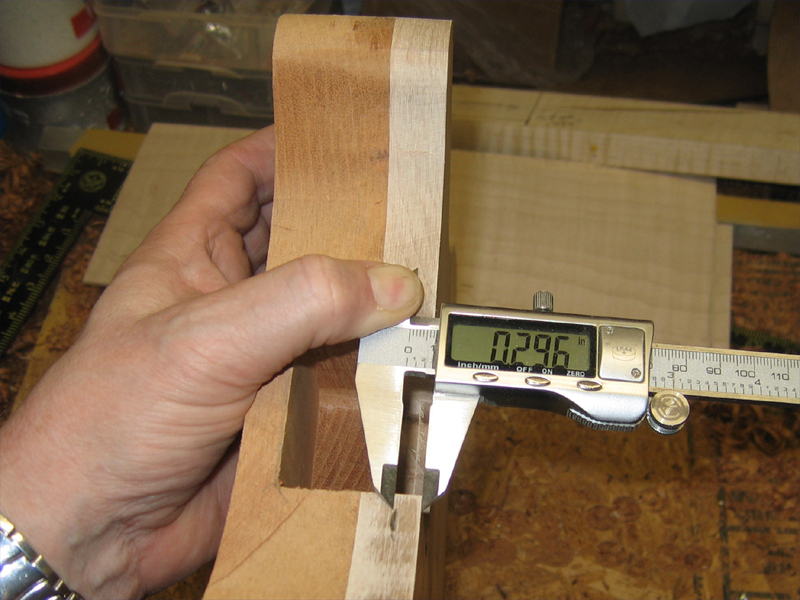

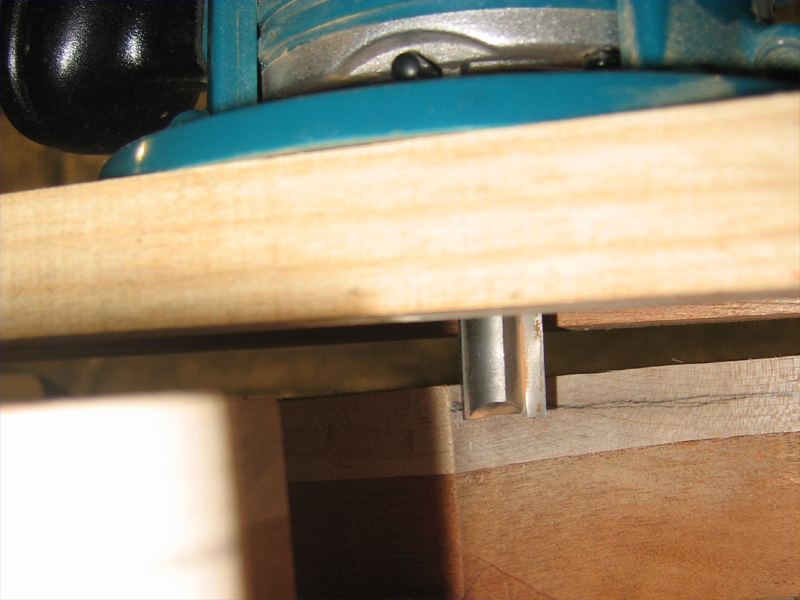

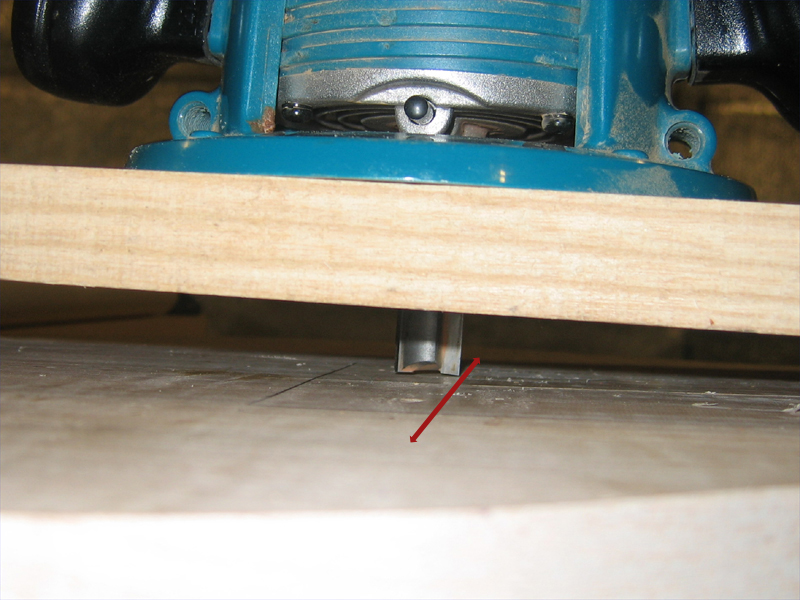

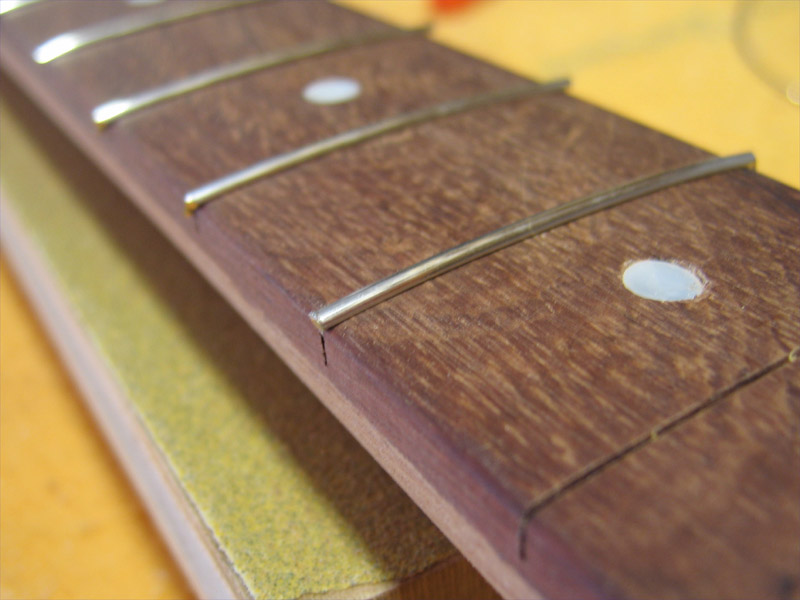

I took another look at the neck angle situation. First. I wanted to get an idea of how the neck is set. I found a few detail shots that shed some light on this.

I can see from these that the thickness of the top, at the neck pocket, varies a bit from model to model. The thickness here would indicate the steepness of the angle...more top remaining, lesser angle. Less top

thickness remaining, steeper angle.

Reply With Quote

Reply With Quote