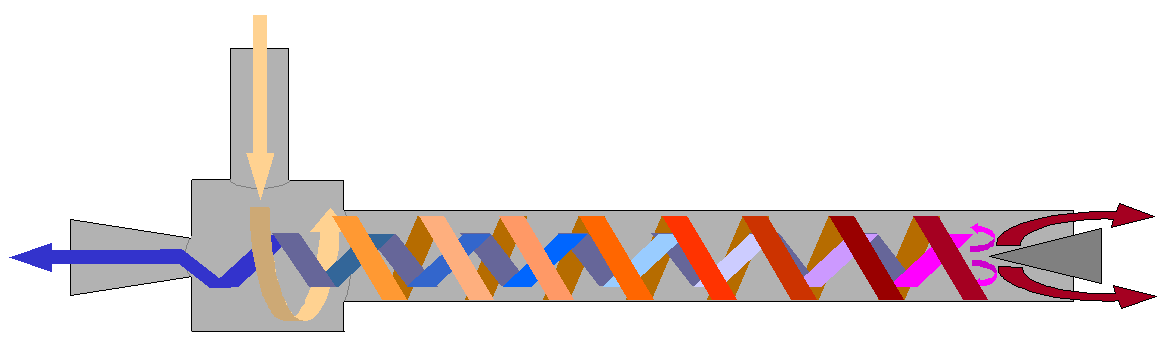

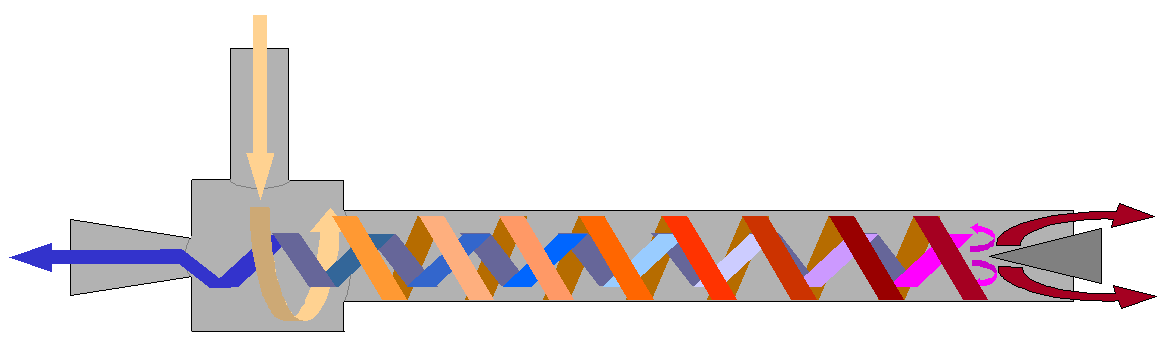

CAGs use a vortex effect (Google Ranque-Hilsch vortex) to transform a high-pressure air stream into a cold stream and a hot stream. There are no moving parts, no chemicals, etc., just a stream of air using physics to either heat or cool.

CAGs use a vortex effect (Google Ranque-Hilsch vortex) to transform a high-pressure air stream into a cold stream and a hot stream. There are no moving parts, no chemicals, etc., just a stream of air using physics to either heat or cool.

Hi-Tec Designs, LLC -- Owner (and self-proclaimed LED guru)

Trotec 80W Speedy 300 laser w/everything

CAMaster Stinger CNC (25" x 36" x 5")

USCutter 24" LaserPoint Vinyl Cutter

Jet JWBS-18QT-3 18", 3HP bandsaw

Robust Beauty 25"x52" wood lathe w/everything

Jet BD-920W 9"x20" metal lathe

Delta 18-900L 18" drill press

Flame Polisher (ooooh, FIRE!)

Freeware: InkScape, Paint.NET, DoubleCAD XT

Paidware: Wacom Intuos4 (Large), CorelDRAW X5

One more thought. If you don't need more than 100 psi, a single stage unit will generate more CFM than a 2 stage. Single stage 5HP compressors usually have 2 cylinders, each compressing room air into the tank. 2 stage compressors use on cylinder to compress room air into the second cylinder and the second cylinder compresses again.

I think Quincy has detailed CFM ratings at various pressures. If my memory is right, their single stage at 100 psi delivers about 20% more than a 2 stage at 100 psi given the same motor size.

I just googled it...interesting device. Have you priced out alternatives? The description I read said it's not particularly efficient and is most useful if electrical cooling isn't available or if there is "waste" pressurized gas available.

If you're running a compressor to run a CAG, maybe a more traditional cooling solution might be cheaper to operate in the long term.

I have a IR in the shop and is not that badfor noise. But if I don't want to hear the anything I just use my CO2 set up, I have a little one in the shop i can carry around and a huge tank that I use to use to frame houses with I have even set the big tank up to back feed into the compressor lines keeping the shutoff on the compressor off"so it didn't try to fill the tank".