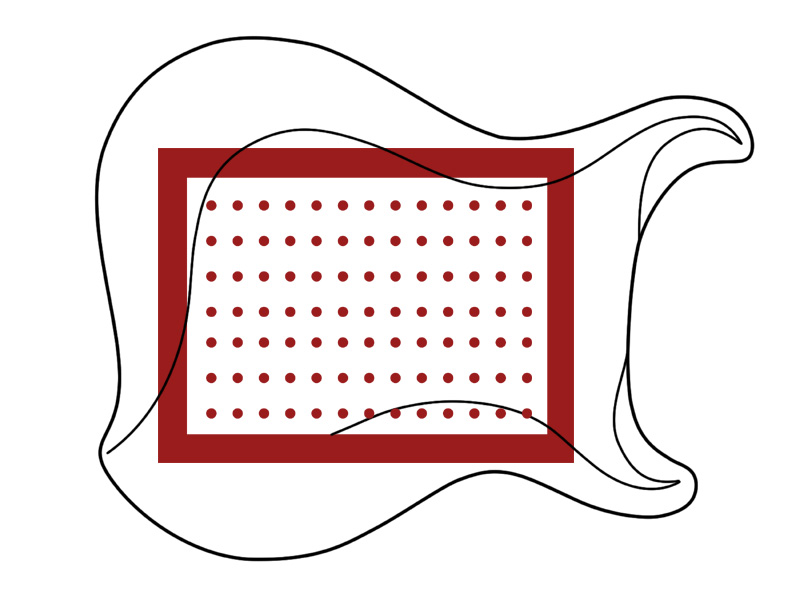

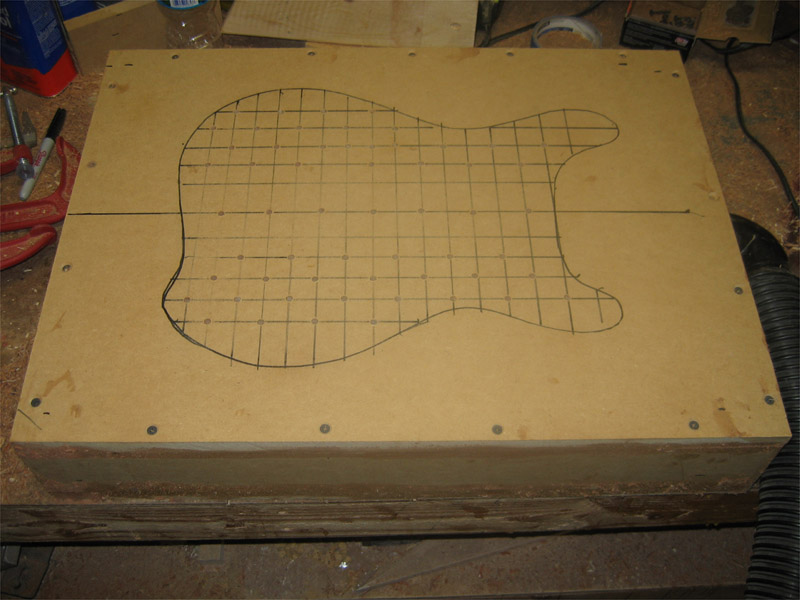

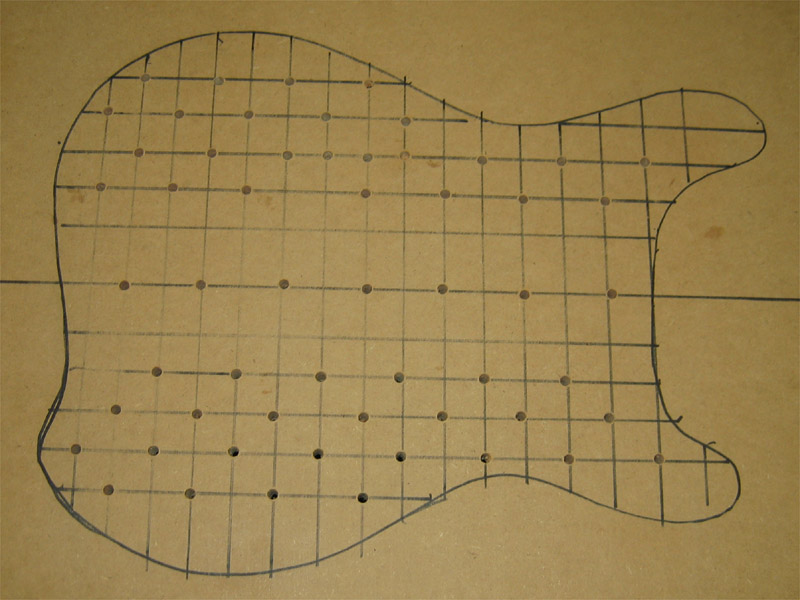

I built this vacuum table yesterday to hold my guitar bodies in place while I do various routing operations. It has strong resistance to vertical lifting but the body slips sideways when moderate lateral pressure is a applied.

It's a basic box made of 3/4" MDF sealed internally with silicone caulk. It's internal volume is 22" x 17" x 3" or almost .65 CF. It uses a 2.5" collector fitting attached to a Delta 50-720 1HP dust collector rated at 650CFM.

As you can see, the only holes are in the table top within the perimeter of the body. My less than logical brain tells me this has the DC working well under it's capacity. Do I need additional venting to increase the airflow and thus the vacuum within the box?

Peace,

Mark

Reply With Quote

Reply With Quote