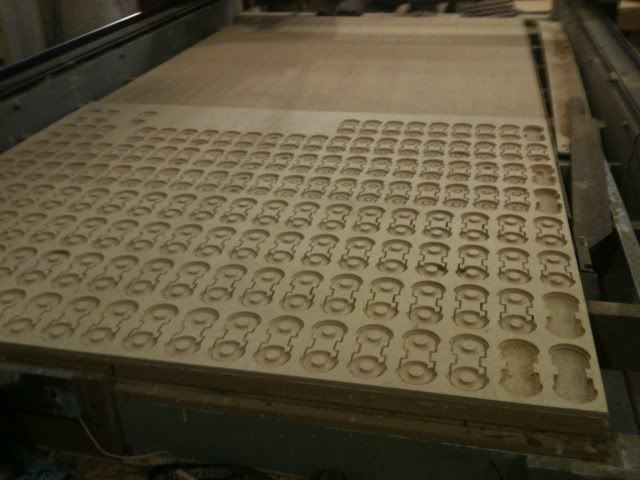

Now I am not using this for high quality work. I will use it to hack up the sheet stock when I remove the scrap from my cnc router. sometimes I end up with a full sheet with lots of holes. my makita cordless skillsaw binds too much and ends up being a pain. I was looking at the makita cordless to save batteries but the think is 180.00 without a battery. thats way to much for what I am doing. a cord would just get caught on everything and I can't take it out to the dumpster with me if needed. so anyone use one and have feedback? so far this milwalkie one seems a good bet.

Milwaukee 2445-21 M12 Cordless High Performance Jig Saw Kit

Reply With Quote

Reply With Quote