I acquired this RAS for 100 bucks.

From the color difference of the motor and the arm, I wonder if it has a different motor than original

dewalt1.jpg

dewalt4.jpg

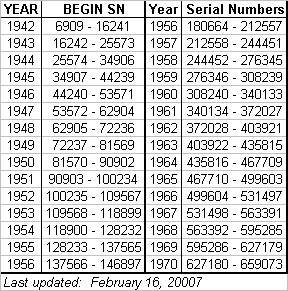

How can I date the motor and saw?

dewalt2.jpg

dewalt3.jpg

Where can I get an arbor nut? and other parts...

Best 12" blade?

thanks

Reply With Quote

Reply With Quote