Hello all.

EDIT: I jsut realized I used the wrong circ in my calculations. The drum is actually 3.5" I've updated the math below.

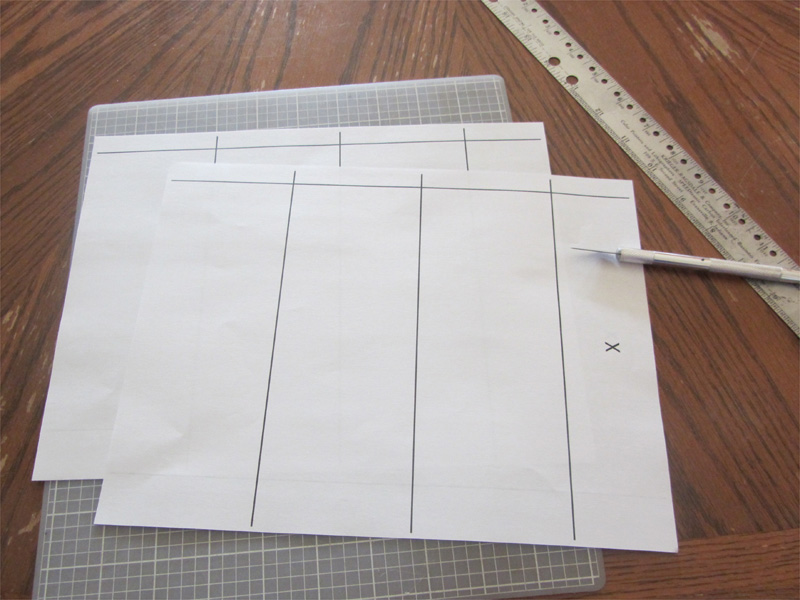

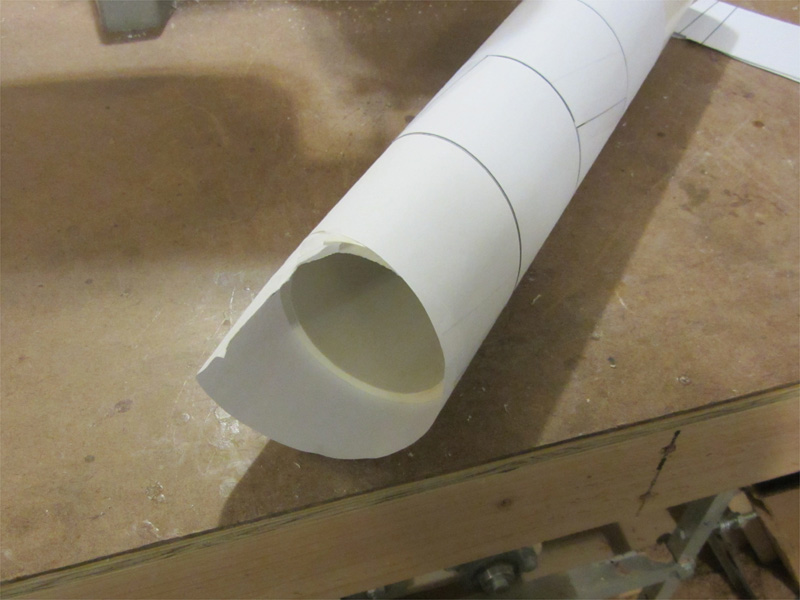

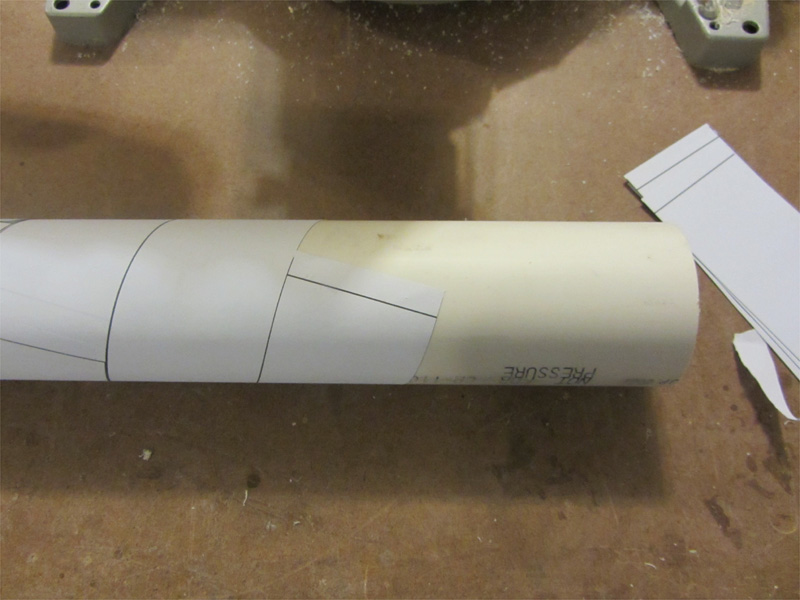

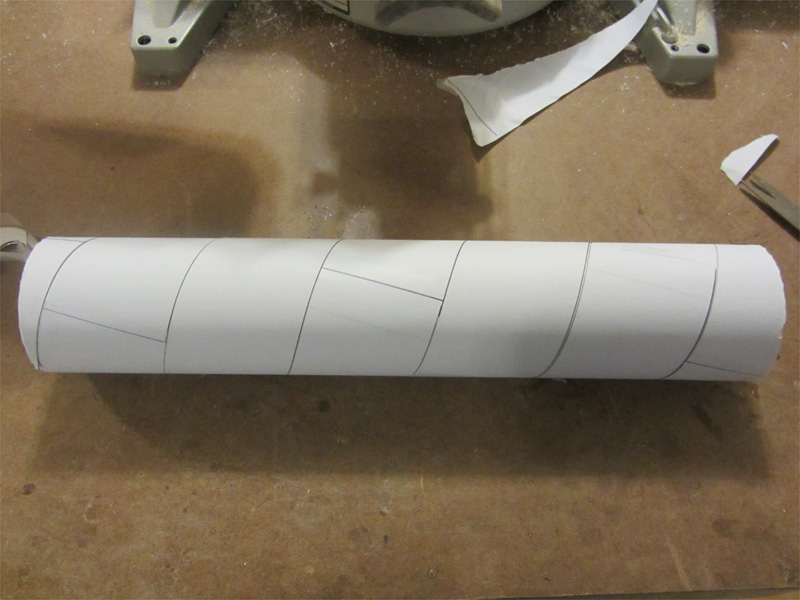

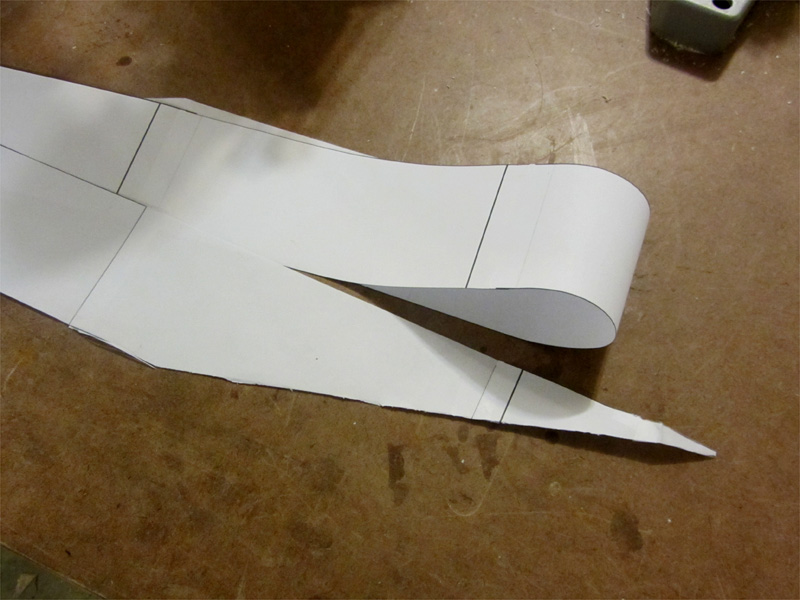

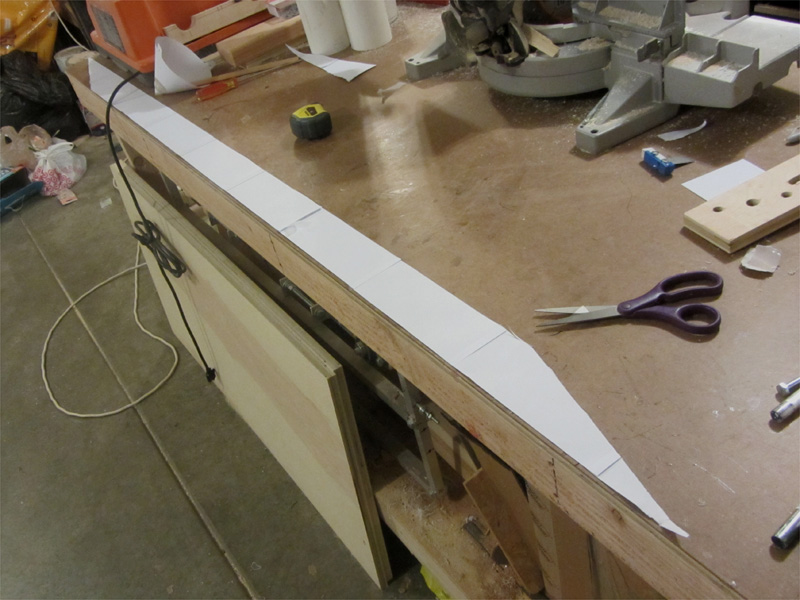

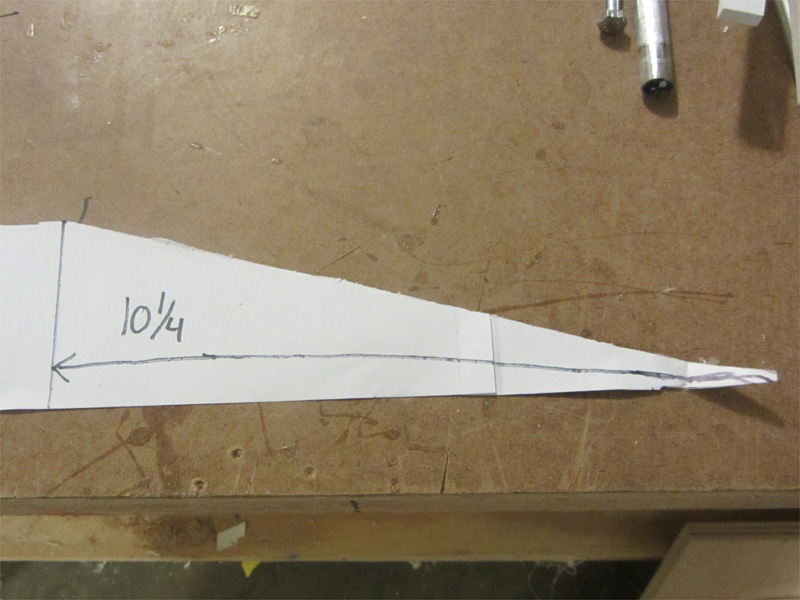

I'm currently building a drum sander with an 18" x 3.5" drum. I'll be using 3" wide paper. Does anyone know of a formula or calculator to determine the taper and length of the paper? I'm thinking I'll use printer paper to make a template but it would be nice to make the calculations to get in the ballpark. There are enough shop-built drum sanders out there, someone might have figured this out.

My initial thoughts are that I can figure length by using the diameter and length of the drum.

3.5" x 3.142 = 10.99". Then divide the length of the drum by 3" to get 6. So, 6 x 10.99" = 65.98"

But, as you angle the paper, does it shorten the length needed to cover the drum or is that a canstant?

Any input much appreciated.

Reply With Quote

Reply With Quote