This is part one of a Neander bombe chest build. I’ll include a picture of the overall shape of the chest in subsequent posts, but basically on both the vertical and horizontal dimension, the chest is wider at the bottom than the top with a semicircular curve built into both the carcass sides and front.

Typically these chests have drawers. I’m building this one out mahogany to hold some audio hi-fi components, so no drawers – the front of the carcass will be open with shelves to support the electronics. There are a pair of amplifiers that each weight ~75 lbs. I love music (but can’t play a lick myself) and am an old school analog guy. That means tube amplifiers (yes they still make those) that generate a ton of heat. The design needs to be appropriately strong to support the weight, but also allow for airflow to keep everything cool.

The LOML is a big fan of Louis XIV furniture which means lots of curves, veneer and classically some other gaudy decorative elements (I won’t be including), if I have any chance of getting approval to bring a new piece of furniture in the house, timing will be key! The only way I was able to finagle getting the 6’ tall speakers into the house in the first place was on a "temporary, trial basis, just to make sure everything works”. For me, anything from BB King/Eric Clapton, along with good whiskey is pretty much heaven!

The overall dimensions of the chest are taken from an example in V.C.Salomonsky’s “Masterpieces of Furniture” (which I highly recommend), roughly 40” wide x 24” tall by 21” deep. Described as “Low Chest Of Drawers Dutch 1725 – 1750”.

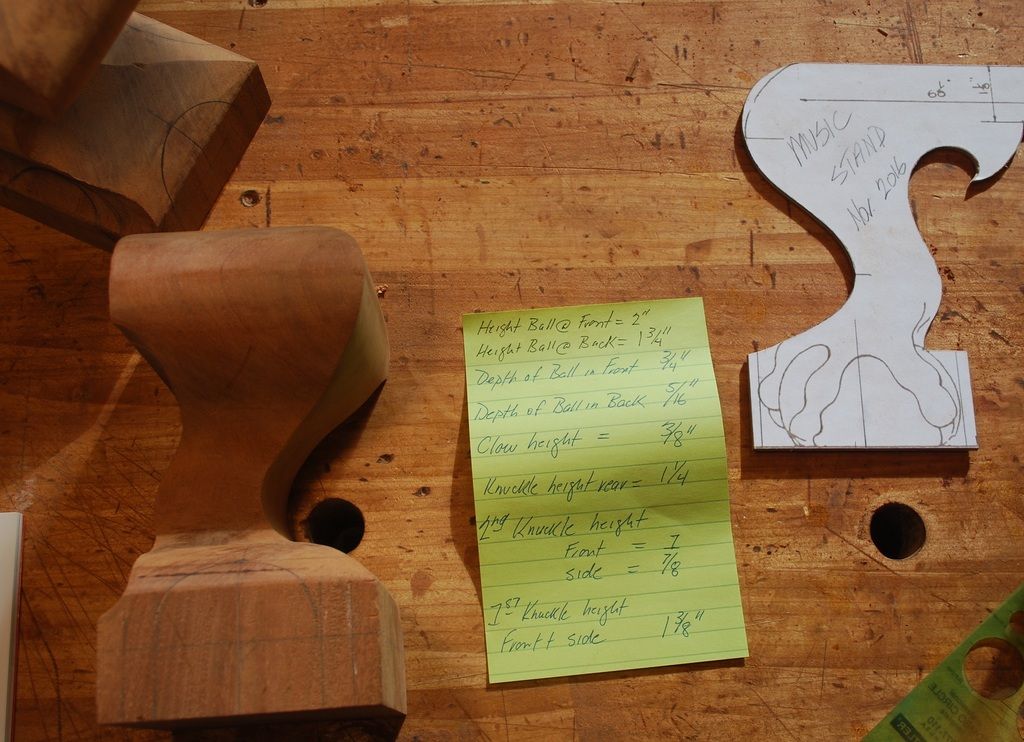

The first part is Cabriolet, ball and claw feet. Here’s the template I use for layout taken from Salomonsky’s book. The instructions for carving the B&C came from “Carving 18th-Century American Furniture Elements” by Tony Kubalak. If you’re interested in learning how to add some carving elements to your furniture builds, I could not recommend this book more strongly. It has great step-by-step descriptions with illustrations for classic 18th-century furniture carvings.

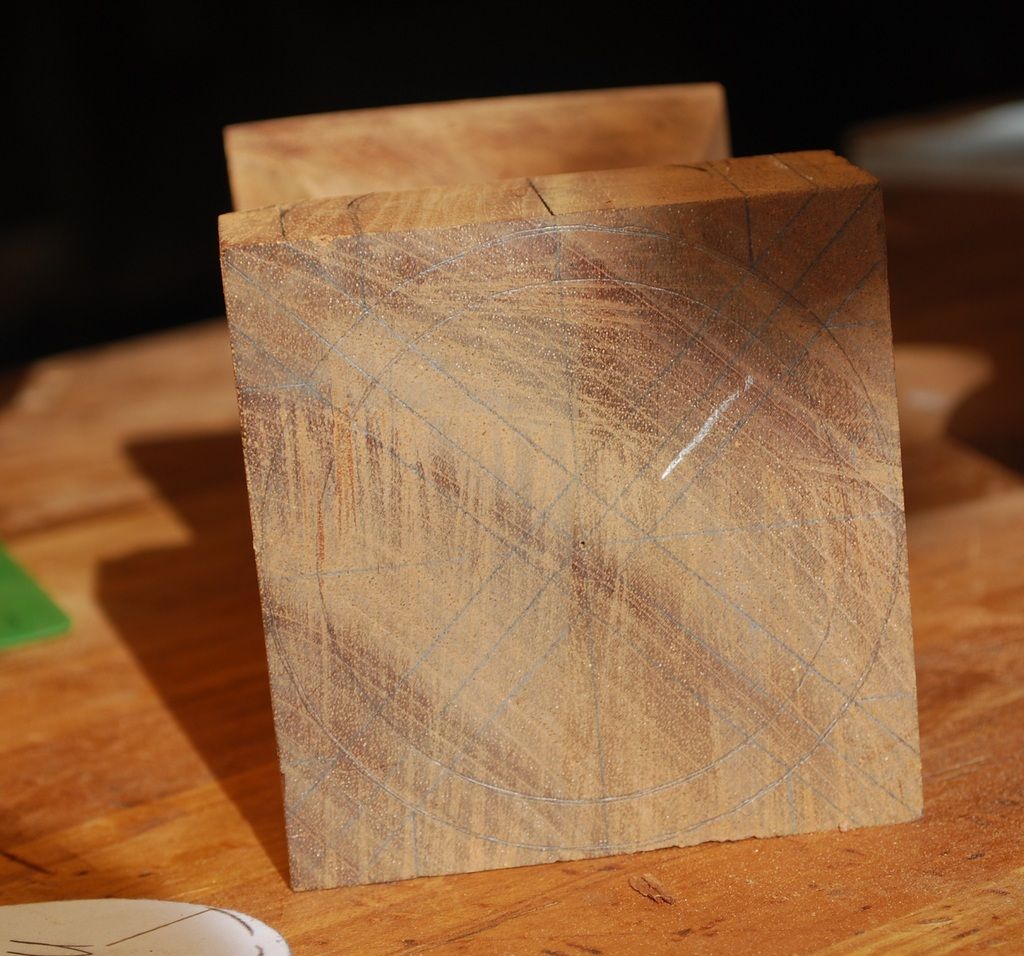

The stock for the feet are 3 ½ in.² mahogany I had left over from another project. This pic shows the layout on the bottom of the foot.

I didn’t take any pictures of shaping the Cabriolet legs (my bad). Here they are after being cut out on my cheesy bandsaw and shaped with rasps/files. You can see the layout lines from the bottom of the foot extended up the sides.

I am absolutely a novice Carver. I did one other set of B&C feed before, the key learning for me was that if you want everything to look symmetrical, you have to work to a ton of defined dimensions for the height, depth of the ball, height of the claws front/sides and back if you want to end up with something that looks reasonable in the end. I’m sure artistic people with the ability to envision objects in 3 dimensions don’t need these dimensional reference points. I’m the least artistic person you're ever gonna meet, my approach is strictly mechanical – measure everything and just try and work each element to the reference point dimensions as best you can and hope it all hangs together in the end.

After layout, first step is sawing vertical limits of the toes. Here’s a pic of tools – carving gouges and rafts/files.

First step is separating the toes from the ball, and then using a # 3 gouge to establish the circular vertical dimension.

Reply With Quote

Reply With Quote

I'll never make them, but I do admire the way you are going about the, Mike. Keep going - I'm watching.

I'll never make them, but I do admire the way you are going about the, Mike. Keep going - I'm watching.