I'm planning on reworking my mitersaw station. The saw is a 10" Hatachi Slider.

What do you guys think of flush mounting a downdraft table under the mitersaw to help with the dust collection?

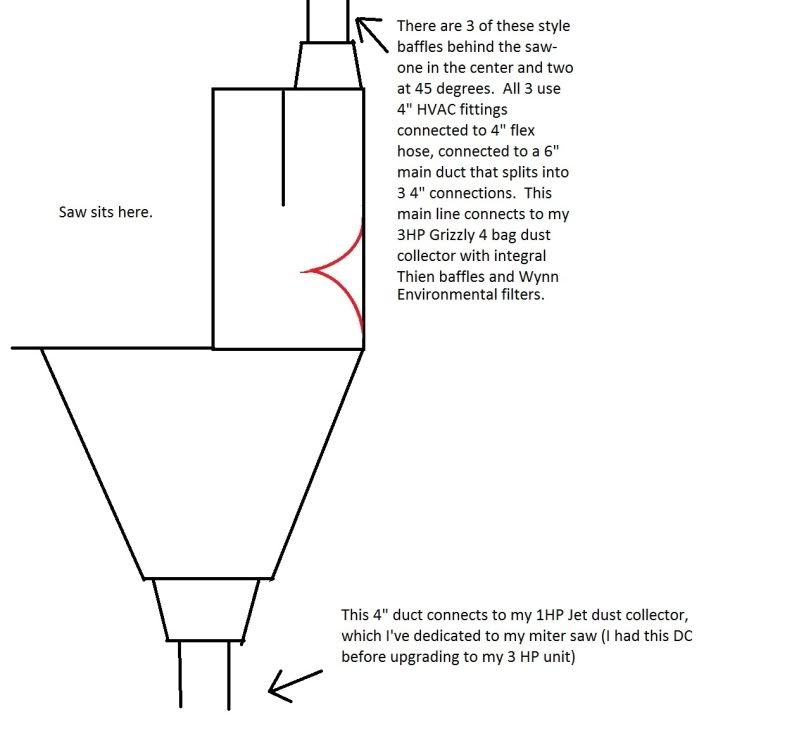

Probably will have a shroud at the back of the saw also to help contain the dust.

This miter saw has about a 2" dust collection port. I used to have it connected to a dedicated shop vac and it is currently connected to my dust collection system. I dont know for sure but it seems to me it may have worked better connected to the shop vac (SWMBO unaware of this) ??

Do you guys tend to use a shop vac or your dust collector at your miter saws?

If i put in the downdraft table I would think connect that to the dust collector for sure but it only has a 2 1/2" port also.

I think I saw in one of his shows that Norm has something like this under his miter saw and connected to his dust collector.

H6396 15" x 25" Benchtop Downdraft Table

Thanks guys.

PHM

Reply With Quote

Reply With Quote