I have a request for a kist (blanket chest) for our family room to double as storage and a place to rest a coffee cup. I have an interesting design in mind, something a little different ... but that is for another time.

I had three rough sawn boards about 14" x 10' by 1 1/4" thick in Curly Marri ..

They all had significant cup and twist, and to retain the maximum thickness the boards were sawn into shorter and narrower lengths, jointed on one side, and then resawn and thicknessed to 3/4" (what is saved from this process runs from 1/4" - 1/2" and will be used for the lower shelf and, possibly, drawers).

This all sounds quite standard, and indeed it was done on machinery, however it was not so straight forward. Curly Marri is very hard and the grain is extensively interlocked. My 8" jointer struggled, and stalled at times. The lunchbox thicknesser left noticeable tearout. And I began to ask myself whether I should just burn the boards instead of building with them.

Marri is not as hard as Jarrah, and it is not as abrasive. However the colour can vary quite a bit, and there are pockets of resin that dry and fall out leaving voids. This is Curly Marri. It is harder to match boards. Not only does one need to match for colour, but for figure and for curl direction.

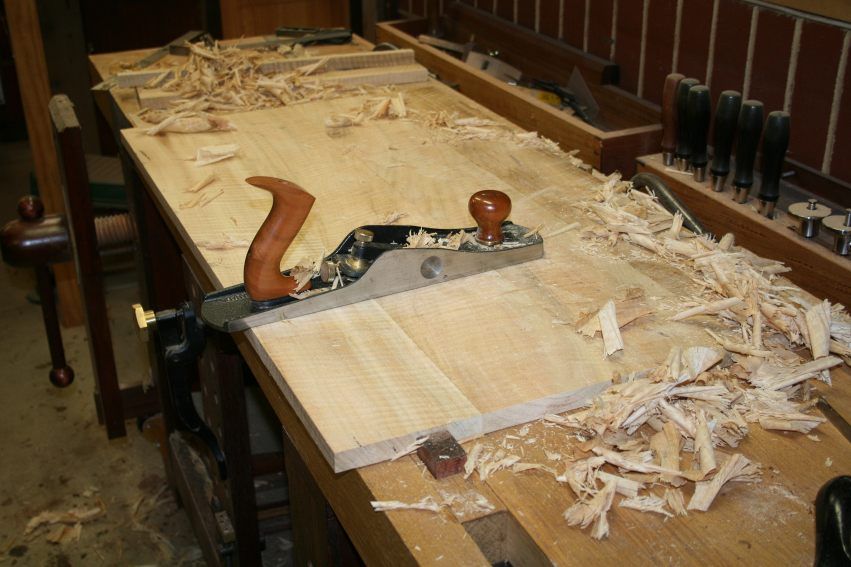

The sawing and jointing took one weekend. This past weekend I glued up panels on Saturday, and then began planing then to final thickness on Sunday. Here are a few photos ...

Traversing ..

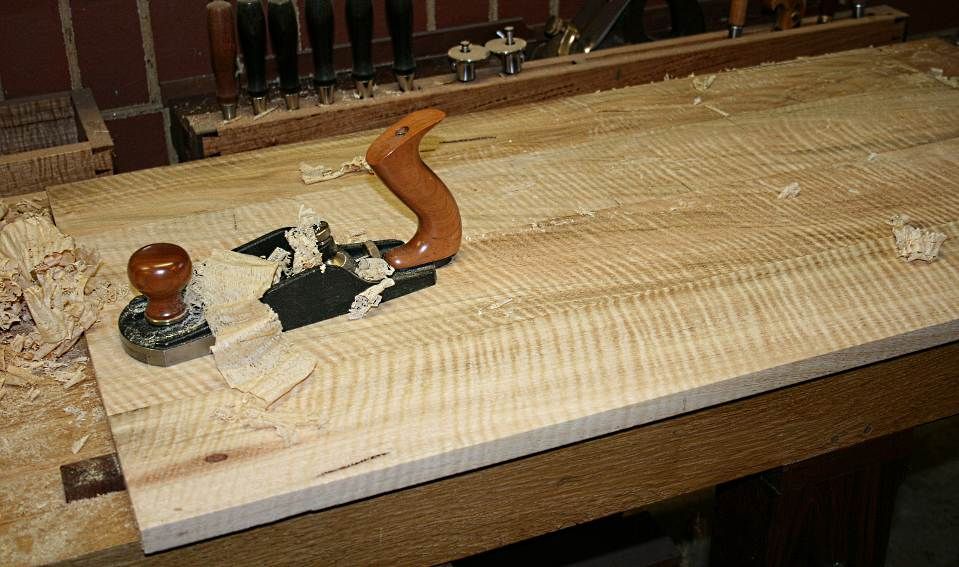

Checking for twist ...

My secret weapon - flattening with a 36" heavy Jarrah jointer with a 3" wide Berg blade ...

Smoothing ... aaahhh, that's what all the fuss was about ...

The grain switches back-and-forth. Some tearout is inevitable. Out come the cabinet scrapers ..

A finished board with a little alcohol to show the grain ..

I'm undecided whether this will become the rear or the front panel.

Question for all - in your personal experience, what is your equivalent of this terrible timber?

Regards from Perth

Derek

Reply With Quote

Reply With Quote