Greetings,

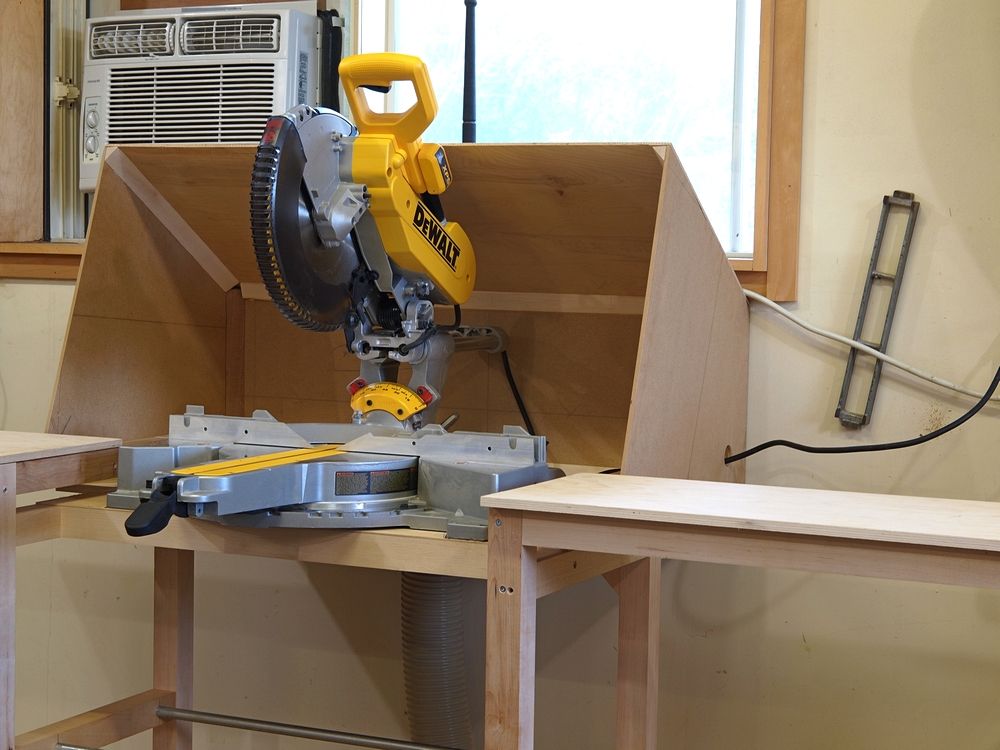

I acquired a Dewalt SCMS late last year and have now decided to retire my radial arm saw.

Until now I've had the SCMS installed on a rolling/folding stand but it needs a permanent home with more features.

The design of the stand required work tables, good dust collection, space for two garbage barrels, my vacuum pump and storage for off cuts that are just a little too big to burn

Instead of your standard ply cabinet I decided to make it out of maple 2 x 2's, M&T, screwed but not glued. For the shelf and wing supports I used electrical conduit. All the legs are height adjustable.

The hood is simply 1/4" material glued and stapled to solid corner braces with a 1/2" ply bottom.

With the saw installed and the front open I performed some test cuts and found that fine dust would billow out about four inches at the top of the hood before being drawn back in.

A 4" strip of wood across the top front eliminated that but I still wanted to close in the sides in such a way as to be adjustable when cutting angles.

After considering various combinations of hinged panels I settled on two panels that simply hang off the front of the top of the hood and can be slide to the side to accomodate whatever opening is necessary.

All done, everything put back in place and ready to work..

Although the hood does appear to be quite deep the whole unit takes up roughly the same area as the radial arm saw that lived in that location.

Note that I removed the tube from the saw that is meant to connect to a shop vac. Dust collection is now upwards of 95%...

Cheers, Don

Reply With Quote

Reply With Quote