Hey guys,

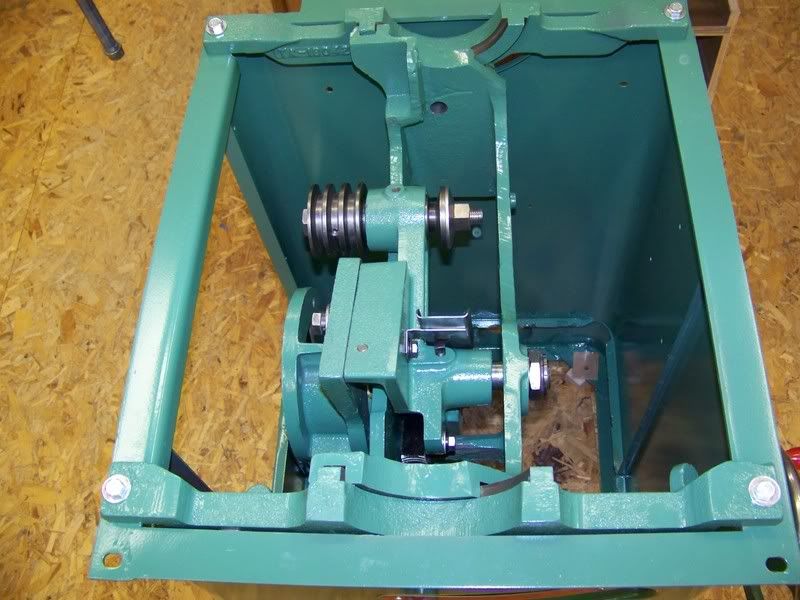

I just bought an older Powermatic 66 table saw (1980) with a 3hp single phase Leeson motor. I am rather pleased with its condition but I have ran into a problem upon reassembling the table. I cannot get the table to "square" up to the blade. Upon further inspection, it appears the arbor is eccentric in the bearing arm. I could ream out the holes on the cabinet to get enough play to make it right but I feel like there is a bigger problem at play here in the bearing arm/arbor. Is this the victim of a poor bearing replacement? Worn out over time? What should I do to make this right? Any help would be very much appreciated. I feel like I got a fair deal on the saw but now I am starting to wonder.............

Reply With Quote

Reply With Quote