Hi Chris

Because some woods are brittle, and when they are very thin they will simply break when planed. The sander is then a better choice.

Tony, the reverse shooting board is only for thin veneer. If you are sanding something substantial, then don't bother with it.

For interest, here is a copy of a post I made at WoodNet in response to a query about the sander:

Here are photos from the Andrew Crawford workshop I attended a while ago. Incidentally, it is entirely possible that Andrew had input into this shooter (I'm guessing) since LV are making and selling Andrew's 90 degree corner slicer for veneer. At this workshop Andrew brought it along the (then) prototype of this.

Here is Andrew:

That is Neil Erasmus with the camera. He is a designer/furnituremaker of the highest order. Google his name. The reverse shooting board I showed is one of his. Neil trained with his father, and said he first used one then.

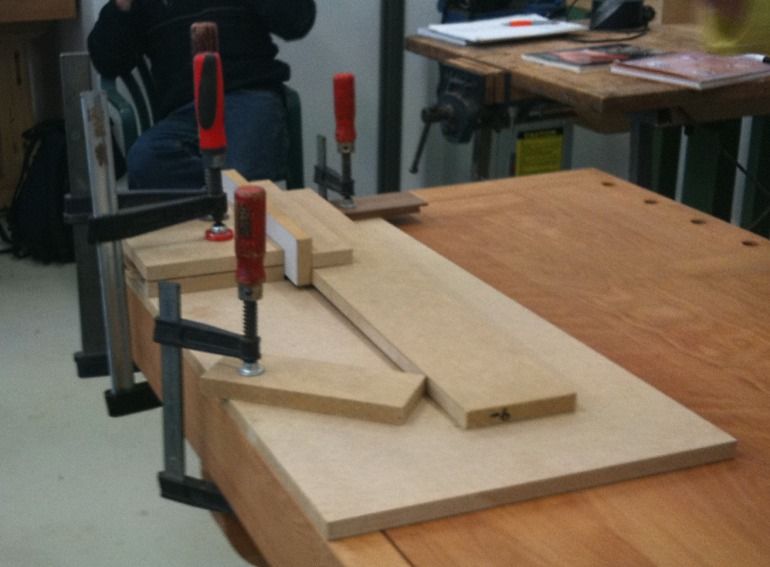

This photo shows the two squares of MDF that sandwich the veneer.The sander shooter is at the front.

The sander/shooting board. The sander is a T section: sandpaper glued to its face and the rear running on anotehr length of MDF. Their is a trailing length of MDF to ensure that the (short) sander has longer registration and runs straight.

Note that the LV sander rides in a track and can be kept short.

Shooting thin interlocked and brittle veneer from woods likes Jarrah calls for a sander. Even a sharp blade in a plane will cause it to break.

Regards from Perth

Derek

Reply With Quote

Reply With Quote