I've buying cheap secondhand tools as I saw them for the past 20 years, and never really used any of them.

But I've been reading recently about hand tools and thought I would like to learn a little bit more. The saw vice and the two Disston saws were the latest acquisition, the planes has been bought here and there, the number 4 on the box is unused.

I dug out the lot now to see what I have got, and took pictures.

And a question about the no 112 scraper plane:

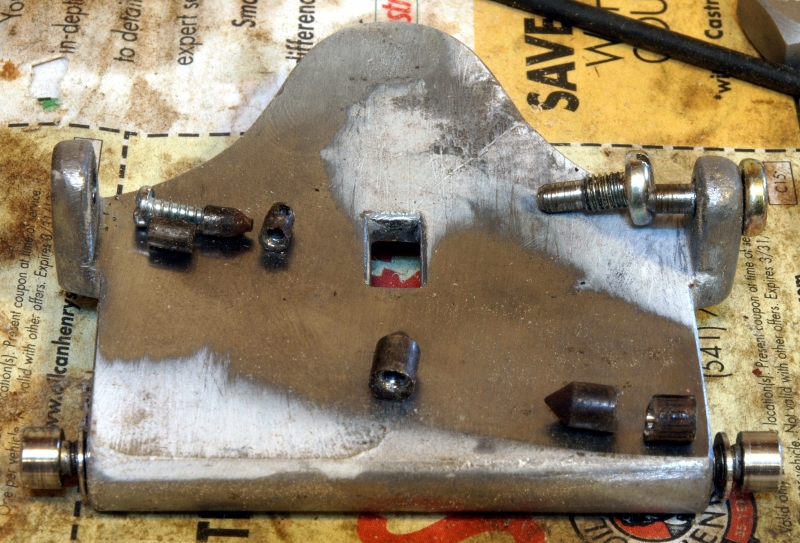

I got it like this, and the studs that the mounting thingy should be mounted on is missing, and I have no idea what they should look like. There are no threads in the holes, and even google doesn't know (Or I don't know what to ask google.) Any help would be appreciated.

Skawe.jpgskawe 2.jpg

Sae.jpgscraper plane.jpg

Reply With Quote

Reply With Quote

.

.

Jr.

Jr.