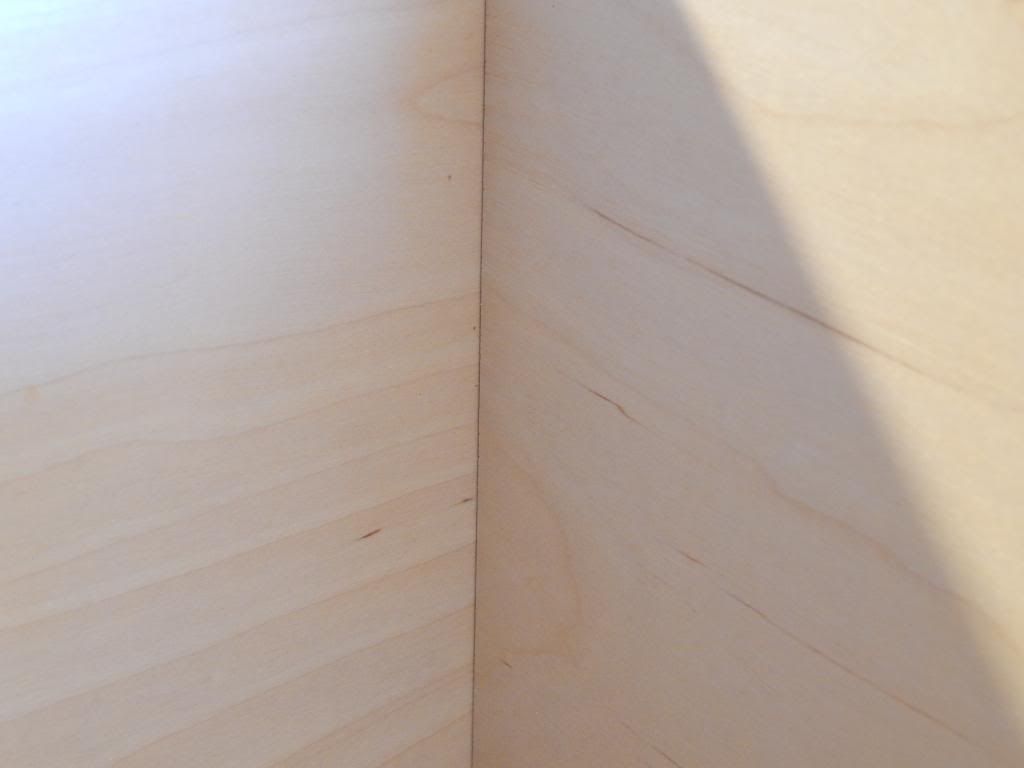

I have found that I am really slow with Woodworking. To cut down a 4x8 sheet of 3/4 plywood, cut to size and Dado took me over 6 hours. Everything came out pretty good, Dado's fit great. Size is 44" X 47"

I need some advice, nothing is glued up yet just put together for fit.

I am planning on staining the entire unit, should I do that before the Glue up?

I would like to try spraying my Top Coat, could someone recommend a reasonably priced HPLV sprayer for a hobbyist.

I have 2 compressors one is 2.4 @ 40psi and 3.7 @ 40psi the other 6.4 @ 40psi and 5.0 @ 90psi (second one seems odd but that is what is printed on the label)I had not planned on using a backboard is that going to be okay?

What would be the best way to mount this unit onto a drywall surface?

I have not decided what to do for doors yet so any ideas would be appreciated.

Reply With Quote

Reply With Quote