OK...I've been wanting to ask this for a while, but I have been (quite frankly) afraid to...

I am building a hayrake style dining table for a young couple. I planned to go with the "Barnsley" styling (see below). However, the plans call for a 6' 4" top and these guys want it to be 8'+.

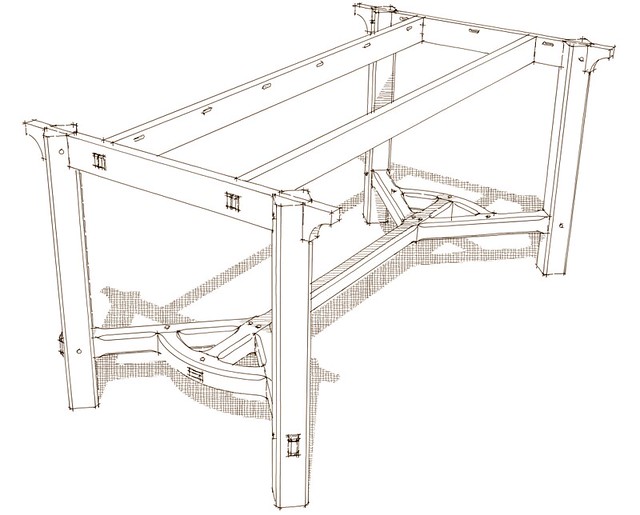

My concern is, well, the length. I'm afraid of the table sagging, I guess. So...my thought was to add a couple of rails. You can see my idea in my attached sketchup model pics.before.jpgafter.jpg

I'd be interested in knowing what you think.

Reply With Quote

Reply With Quote