Originally Posted by

David Weaver

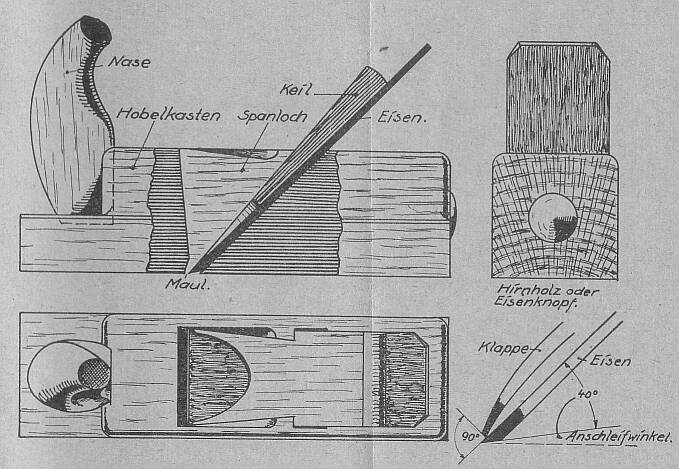

Hopefully if nobody else other than Steve, Kees and I want to build them after this, it'll at least clue people in what to look for when they're shopping old wooden planes, and then after that, how to make the wedge if a new wedge needs to be made.

David, I don't know that I want to build one right now as I have enough other projects, but I can see myself building one in the next couple of years. This has been very educational for me. I'll likely build a Krenov plane first and then a non-laminated plane.

Shawn

"no trees were harmed in the creation of this message, however some electrons were temporarily inconvenienced."

"I resent having to use my brain to do your thinking"

Reply With Quote

Reply With Quote