Ended up with 209 sheets sprayed this week.

Did this drawing too on the Griz site.

Also got a little bling for some of the upper outlets.

Ended up with 209 sheets sprayed this week.

Did this drawing too on the Griz site.

Also got a little bling for some of the upper outlets.

Glad its my shop I am responsible for - I only have to make me happy.

I bought it from the Chicago craigslist. Ive even found two and the other sizes of them. I paid $700 for the largest one. Ive added a platform and the wheel kit. It has really made it supper moveable and i have not been on the scaffolding since i got it. But the scaffolding is so much larger it does not fully replace it. Doing my wallsi may use scaffolding too. Really i am thinking they will compliment each other.

Glad its my shop I am responsible for - I only have to make me happy.

This weekends accomplishment:

New porch lights installed

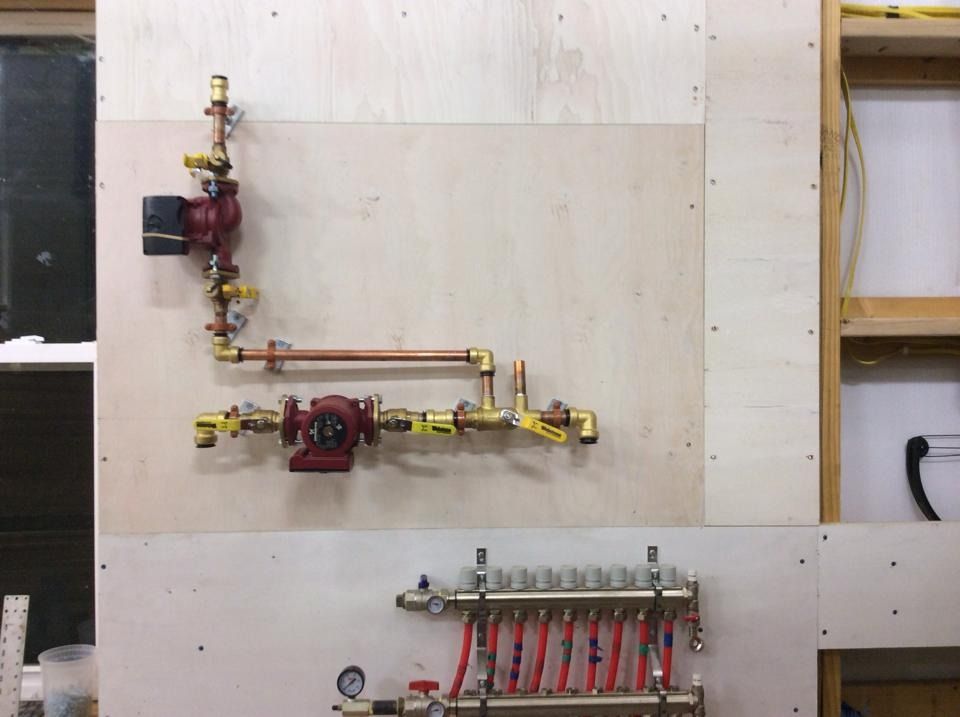

Radiant floor heat wall insulated and built out:

Radiant floor heat components soldered and laid out:

Pumps and valves installed on wall:

Glad its my shop I am responsible for - I only have to make me happy.

Mike I'd like to make just one little suggestion if I may please?

Before doing so, I want to "preface" my comment with this 'over rider'.

1. I am from another country half a world away (thus we have different building codes) - i.e. no snow ever etc!

2. I worked 20 years with my father who was a master builder - earned his Builders registration in 1952.

3. We built a very similar construction pole barn together once a long time ago (30+ years now) so my comment is based on personal experience.

It was 30 ft x 30 ft - the wall poles were 4 x 4 hardwood (Mahogany).

It had a "Mansard" or "double pitch" barn roof - corrugated metal clad.

The "trusses" were made same way as yours by my father - Gang nailed out of pine.

The Roof Purlons were 4 x 2 Oregon.

I don't know if your in a tornado area at all?

I am definitely NOT... being downunder we get cyclones not hurricanes - but I was well below that cyclone zone (34 south Lat versus the cyclone zone starts at 26 South lat and above towards the equator) so considered a low risk revolving tropical storm zone.

That said - I got hit by one in the middle of the night! (A tornado or it's down under equivalent - we have different names for them coz they are infrequent - 1 in 100 or 1 in 200 year events and very "localized" variously called "Cock-Eyed-Bobs", "Willy-Willy's" and a few other descriptions..location dependent). Over the ocean we call them "water spouts".

The one hit us was "a tornado" - no other description for it.

I woke in the middle of the night and our whole house was shaking like a earth quake - the bed shaking woke me.. the noise.. well I have sat thru a cat 4 cyclone since & noise was same.. shrill howl like a banshee - nothing on earth compares.

Initially I believed it was an earth quake - I lived thru one of those back in 1964 as a child - so I knew it was a earth quake... until the eye of the tornado passed over us and everything went eerily still for maybe 30 seconds - then all hell broke loose again.

That's when I realized it was a tornado..

After it passed, I poked my head outside in the dark and couldn't see any obvious damage anywhere - so went back to bed.

In the morning the kids were up before me & came racing back in to the house......"Dad, dad" they are yelling - "come see, come see - the Shed Roof is GONE".

I am thinking - what are they on about? A sheet of roofing iron been torn off or something?

Went outside in my dressing gown and slippers... They weren't kidding.... the entire roof was GONE - vanished... a complete top story effectively.... missing i.e. no where to be seen!

Then I saw down by the river, where the tornado had spiraled off, at a bend in the river come thru the trees and up the hill thru where my shed stood.

There were trees along the river, 250+ years old - 4 feet in diameter and 60 feet tall - twisted off at the trunk half way up, as if a giant "hand of God" had grabbed them and torn them in half...like match sticks, and the top half crowns.... also completely missing - no where to be seen, Maybe 15 tonnes or more in the top half of the tree - just gone!.

You could "see the pathway of damage" straight up the hill from the river, to my shed....maybe 100 feet wide?

It went thru another couple of neighboring farms, also but hit no other buildings in the town or surrounds - just my shed, dead on hit & then a few more mature hardwood trees in the pathway behind the shed as it wandered off to who knows where!.

There were some 4 x 4 hardwood posts attached to the roof also gone - torn out of the ground along with their 2ft x 2ft concrete footings & metal stirrup - they were also gone.

I eventually found what was left of my roof about half a mile away at the far end of my farm.

Those roof trusses?

Wasn't a piece of pine.. any longer than 4 inches... that I found left - all the gang nail plates here there and everywhere broken clean at the edge of the plates both sides.

Our mistake?

We only skew nailed the trusses to the top plate from each side. I SHOULD have used inch galvanized metal strapping to tie over the top of ALL the trusses and tek screwed them to the top plates & down a foot into the posts all the way around the shed.

Once the wind lifted one corner of the roof - it took the lot & I believe it if was tied down to the posts with metal strap it probably never would have got that first corner lifted!.

Sadly the shed also wasn't insured!. The metal cladding alone was $7K and that was like 30 years ago prices (probably double today)!.

So I am "respectfully" suggesting - that you maybe put some 1 inch galvanized metal strapping over the end of each roof truss and try to tie the top plate and trusses down to your 4 x 4 posts - so that theres no way for the roof to lift...

Those trusses will bear any weight you have up there forever, however once they "deflect" as a roof "peels back"...they have next to zero strength if they aren't tied REALLY well into the posts below!

Your concrete floor should keep the posts and their footings in the ground... so if you can keep your roof on... well you SHOULD withstand any sort of localized "twister" event - Maybe not a full on Cat 5 Tornado - but smaller wind cells - maybe you;ll stand a far bigger chance of coming off unscathed.

You may NEVER see such an event - BUT if you should - you will sleep easier knowing those trusses are tied into the posts and footings and top plate with metal straps and long tek screws.

Sorry if this suggestion is redundant... like I said I don't know your local building code.. where we built it was done to code, coz we aren't (weren't) considered a cyclone prone area - up north above the 26th parallel we have a more stringent "cyclone" rating building code - but not for that area at that time.

I have in years since built an engineered metal shed with steel portal trusses etc.

Don't know if you can see it in this photo,

But although the metal "top hat roof purlons" are tek screwed to the steel portal trusses, I STILL have every purlon / truss overlap strapped down with 1 inch galvanized metal strap for extra strength.

I only had to lose the one such roof (and take the hit to the hip pocket for not being able at the time to afford the insurance) to 'learn my lesson'.

Your mileage of course may vary, I just offer the suggestion for what little it may be worth.

Cheers.

Last edited by Ian Moone; 10-05-2015 at 11:41 AM.

Iana LOVE that shop. Can you zoom a clear picture into that straping for me sometime. THANK YOU for taking teh time to post that. Man what an ordeal. Thank you for teaching me about your lesson!

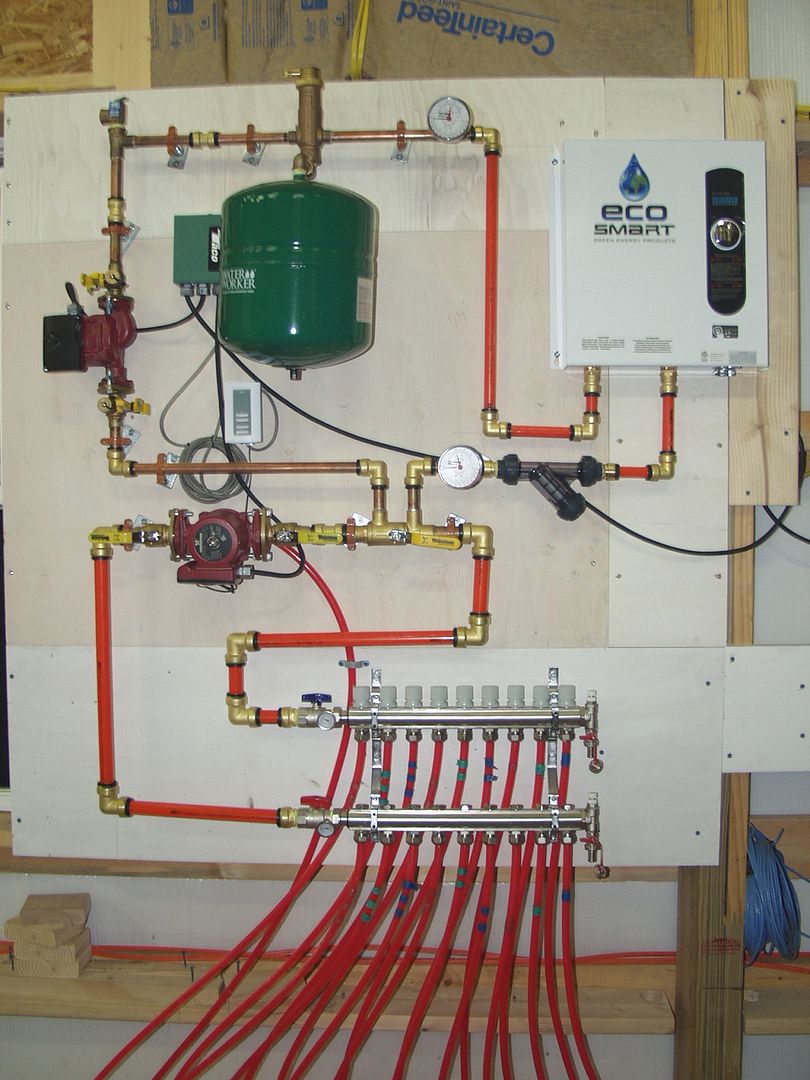

Tonight's progress. Rest of radiant panel built. Pretty nice copy of the HydroShark radiant panel only with nicer pumps and a ton cheaper.

Now I will mount the hot water heater and plumb up the pex to these AMAZING Watts Quick Fit connectors. They are soo nice! Pricey but made the install a million times easier.

Glad its my shop I am responsible for - I only have to make me happy.

Sure thing.

In essence just strap everything you can down!.

To prevent portal trusses poles/legs being lifted out of the ground by strong "wing in ground / low air pressure" events forming in high winds behind the pitch of the roof (think air plane wing lift), i did this above (pls excuse the rough diagram to my concrete footings to key them better into the ground AND also key them via their pyramidal shape into the concrete slab as well.

In essence the ONLY way the shed can LIFT - is if the whole thing goes... including concrete slab, footings, walls & roof etc as one whole thing...

Who knows what the forces of nature REALLY can do when they get determined - but any video of tornadoes hitting houses etc - will give you a pretty good idea.

The rotational (twisting) torsional forces are also considerable in such localized twisters, so every wall, and roof panel is likewise cross braced inside to help prevent the thing deforming.

Your contractors did a fine job erecting your barn from what I can see. It seems to be withing normal expected construction standards to my eye (not knowing your relevant codes).

I just think its possible to do more is all.

If it were me?

I would make up 3/16th Galvenized "T" plates (pre drilled) that Lap over each top plate joint above your poles And the bottom part of the T shaped plate comes down the inside face of the pole and tek screw (or coach bolt) that into place at each join to keep the top plates all fastened to each other but also fastened down to the poles. Then run your metal strapping up over the ends of the trusses above the top plates and back down to your metal T plates and Tek screw them in as well.

The last thing, is where you have those 2 x 2 pine bracing along the bottom chords of your trusses that you tend to run electrical's along from end to end of the barn for lighting, their primary job is to prevent those truss bottom chords from deflection at all. As I said earlier the strength of the trusses is all downwards for bearing the weight of the roof - that's how they are engineered.

But how do the perform in the opposite direction? (i.e. wing in ground low pressure LIFT of the roof - especially in torsional wind events like tornadoes).?

The roof sheets do diagonally brace the trusses at the top to prevent any deflection that might weaken the load bearing ability of the trusses, however the only prevention of the bottom chords deflecting is that little 2 x 2 pine brace that your running electrical along! It might be nice to see that strengthened maybe...perhaps even metal ceiling rafter hangar brackets added to join the bottom chords and braces together for extra strength.

It's all about preventing deflection of the truss in any way & the bottom chords of the trusses are crucial & don;t have all the roof purlons and sheeting to brace their position to prevent deflection.

Those are the ONLY things I can think of. & I have no idea what the likelihood is of any revolving wind cell type storms in your area! Supposedly we never get them - but the one hit my shed was a doozey!

I guess if we are undergoing radical climate change as so many seem to suggest - then I am saying it can't hurt any to plan ahead and take what precautions you can... after the event is too late (a lesson I learned the hard way)!

Its a very impressive barn build - I could only dream of having that much space.

My little 21 x 25 ft (6 meter x 7 meter) metal shed is no comparison.....and is already jammed full with little room left to work!.

It was a very simple home construction job.

East to see that I am fast running out of space!

If it were twice the size - I'd still manage to clutter it up!.

Mike, take a look at Simpson Strong-tie (or equal); specifically "hurricane strap". They tie rafter to top-plate, and top-plate to wall. Similar can be used for wall to slab/beam/foundation (forgot the name). Really useful in tornado alley or coastal areas.

Thanks again for all that info!!!

Tonight I mounted the boiler and ran the 3/4" pex to it from the panel components. Also ran 1" pex to the 9 loop manifolds that go too and from the floor.

Glad its my shop I am responsible for - I only have to make me happy.

I needed to get some wall up to mount the disconnects the in wall circuits for the boiler will terminate at by the panel. The boiler has three 40 amp circuits with 8ga wire ran to disconnects. You can see the pencil marks where the disconnects will be. I am using outdoor air conditioner disconnects that I will mount tomorrow. To do it correctly, I decided to just start at the floor and get some slatwall up. I am using a 2X6 against the concrete as my kickplate. It is attached to the posts and and also a 2X6 in the middle that connects to my bookcased 2X6. I got three sections built and installed. Everything is insulated with R19 batts behind everything. Notice those 120V and 220V flush outlets through the slats - that took aligning the box hole between the solid wall board on the back and the slats in front. I used the CNC to cut the box holes out in the exact same spots. Then with the help of the adjustable boxes I could install them through 1.5" of plywood. SWEET!!

Last edited by Mike Heidrick; 10-09-2015 at 2:23 AM.

Glad its my shop I am responsible for - I only have to make me happy.

Teaching Megan, my 8yr old, how to wire up some disconnects. She is getting the last box ready to connect up the last circuit. She is just like her dad, she gets shown how to do something and then immediately wants to teach it back as a way to reinforce to herself what she just learned. She gave me a lesson about 3 minutes later. Kids ROCK!

Glad its my shop I am responsible for - I only have to make me happy.

Here is a Video of the Hydronic Heat system I built. It is a walk through of all the parts I used. Trying to help the next guy not have to research everything so much in a system like mine.

Glad its my shop I am responsible for - I only have to make me happy.

I have just one question.

Does the glycol / water system conduct electricity?

It's just that you have Brass (joints), Copper (Pipe), Cast Iron (pump Housings), and Steel (Expansion tank) all plumbed into one system.

I am wondering (to myself mostly) if the least noble metal in the system might not give up it's electrons to the more noble metals and you end up with electrolysis or "in effect a wet cell battery" (dissimilar metals in an electrolyte) so possibility of galvanic corrosion?.

Perhaps there's even aluminum components inside the pumps perhaps (so a possible 5th metal).

I am thinking (to myself) - should there perhaps be some kinda 'zinc' (Hydral/Mercatel) 'sacrificial anode' added within the system, to protect the expensive metal components from premature failure from either electrolysis or galvanic corrosion maybe?

Heating under floors - is not a topic ever come up here... its always hot & never gets cold here.... now installing refrigerated air conditioners we know something about!

Keeping your heat within the shop is one of the big issues for expelling air from cyclone dust collectors, by venting them to atmosphere - is again something we never have to worry about!

If your working with any kind of particle board, MDF, Melamine boards, etc manufactured with urea formaldehyde glues - the out gassing of formaldehyde is potentially very cancerous and normal filter bags on dust collectors just re circulate that gas thru your shop day in and day out - so venting it to atmosphere from a cyclone is far more preferable, but then all the expensive warm air you paid to heat up, goes out to atmosphere with it!.

I think its called "a catch 22 conundrum" - freeze to death or die of esophageal cancer from the formaldehyde!.

Don't worry, it's just me 'musing' to myself.

Thank you for the comment Ian. Yours is the first forum post since my video was published today and this was prob the biggest shed stress of 2015 - betting on a lot of reading I have done so far. This one equaled building my cnc router and not knowing if it would really work or not. I appreciated the musing for sure.

Glad its my shop I am responsible for - I only have to make me happy.

Probably the time difference, middle of the day here.