We shot over 200 over two days doing different positions and movements.

We shot over 200 over two days doing different positions and movements.

No work last two nights - CUBS!!!

Go CUBS!!! Mike, this is my favorite thread on this site. Keep up the stories and pictures

Cleaned up a bit, made a sign for a customer, and had Lily's 7th B-day party out there. About 20 seven year olds and about five moms came over. Working on walls again in the AM.

Glad its my shop I am responsible for - I only have to make me happy.

Mike - Been watching this thread since the start, awesome shop. Interesting about lots of folks saying this or that is overkill. It's your shop, if you have the means and space and time to do this, good on ya! I'd love to have a shop this size with all the goodies you have. Your work quality is great too. Nice to see anybody with the skill sets to do stuff like this. I love doing stuff myself. I tackle all sorts of stuff I've never done before. I've rebuilt all sorts of old woodworking machines one bolt at a time and really learned a lot along the way (with the help of folks on this and the OWWM web sites). I get a great amount of satisfaction doing exactly what you are doing but on a much smaller scale. Keep up the great work and enjoy your shop with your family and others. Randy

Thanks Randall and everyone!

Made these today. Going to surprise the customer with a pair of Freebies ( in that cool tv announcer voice).

Found another steal. Mobile recliners from an eye surgical center at the local restore. Will make awesome shop theater seating. $33.75 ea.

They have large locking casters, recline flat, industrial covers, folding side, and handles for chair races lol.

Now to make some swing away cupholder snack tables that use the iv pole mounting bracket.

Wow...those chairs are a find!! Your spokes-model seems to approve of them, too.

--

The most expensive tool is the one you buy "cheaply" and often...

Those chairs will come in handy if you're ever chased to the barn for a few nights. At least you have a nice "dog house."

I can't decide whether the CNC is looking at those stacks of ply thinking "man I am hungry, lemme eat" or "nooooooo".

Of all the laws Brandolini's may be the most universally true.

Deep thought for the day:

Your bandsaw weighs more when you leave the spring compressed instead of relieving the tension.

I worked until 12:30am last night and finished the wall insulation and wall mount 2X6s. Tonight we are watching a movie in the new chairs.

Glad its my shop I am responsible for - I only have to make me happy.

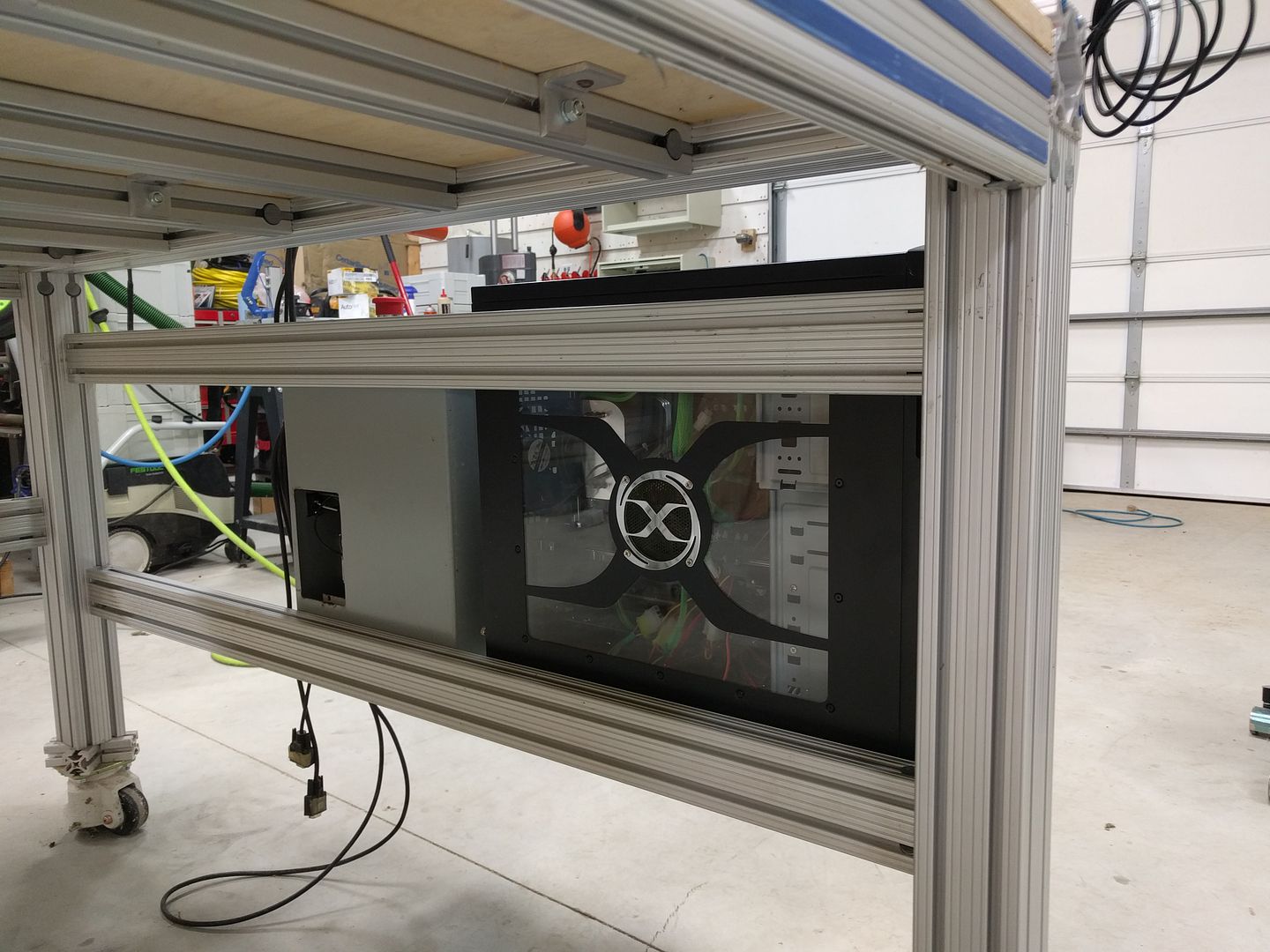

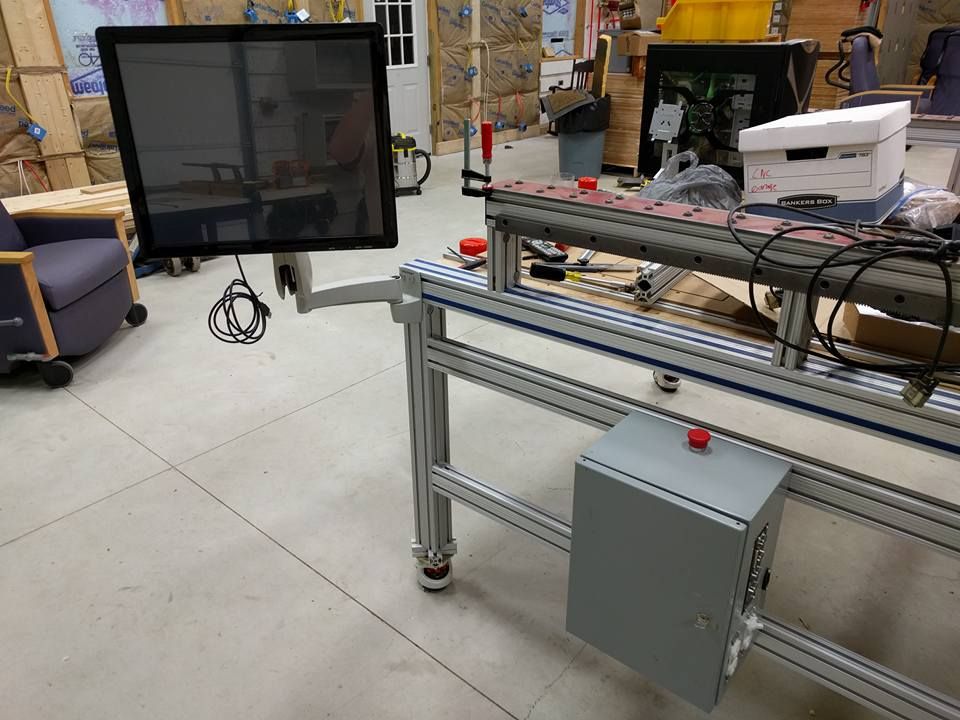

A buddy gave me his CNC 5'X5' router earlier this year as he lost his shop a couple years ago. His machine is on casters and is mobile. I am getting it running in the new shed to cut slat outlet box holes. I needed to attach the controller and computer to it as he had them sitting on a side table when he ran the machine at his shop. I cut two lengths of 15 series 8020 with a non-ferrous blade on my SCMS, and CNC milled 13/16" holes for 8020 anchors to mount them flush on my knee mill. There is a video of that linked.

Here are the two rails installed on the machine, the CNC Gecko G540 controller cabinet installed on those two rails, and I also installed an Ergotron monitor arm on the front and a touchscreen monitor.

Glad its my shop I am responsible for - I only have to make me happy.

Computer case mount done