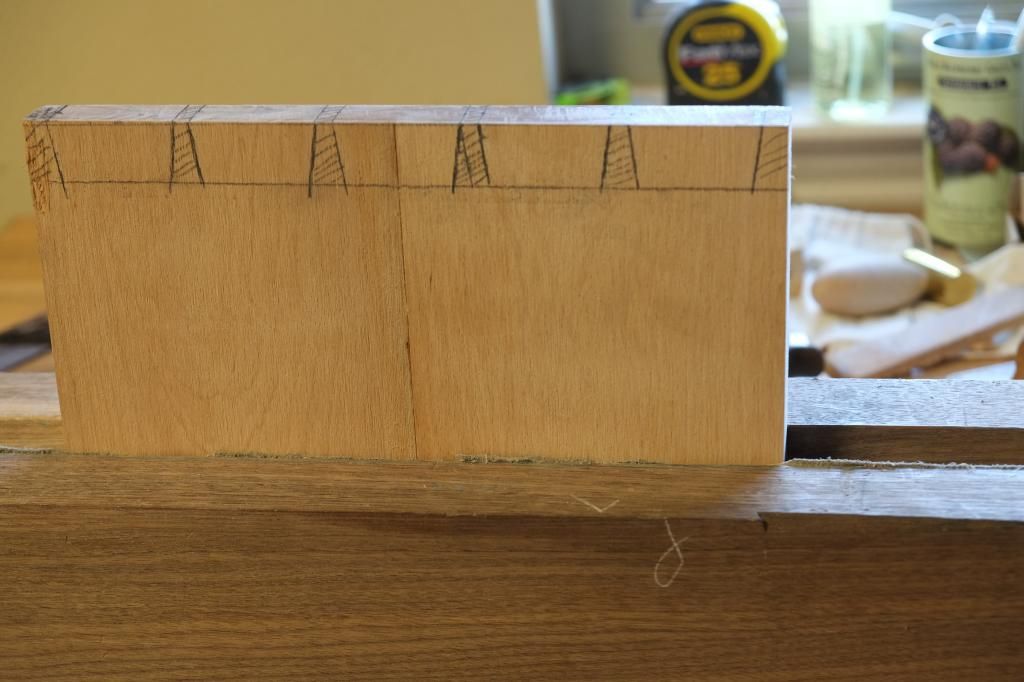

I've been working on building a Dutch tool chest. If I'm able tomorrow, I'm at the point to cut the dovetails for the bottom. This will be my first attempt at dovetails. Feel pretty good about having all the book learning. I'll either succeed or my large chest will become a small chest.

Reply With Quote

Reply With Quote