I am having issues with vertical banding when engraving anodised aluminium. Initially I noticed this when trying to engrave a photograph but have now discovered it to be an issue on black vector fills, which rules out artwork as the cause of the problem.

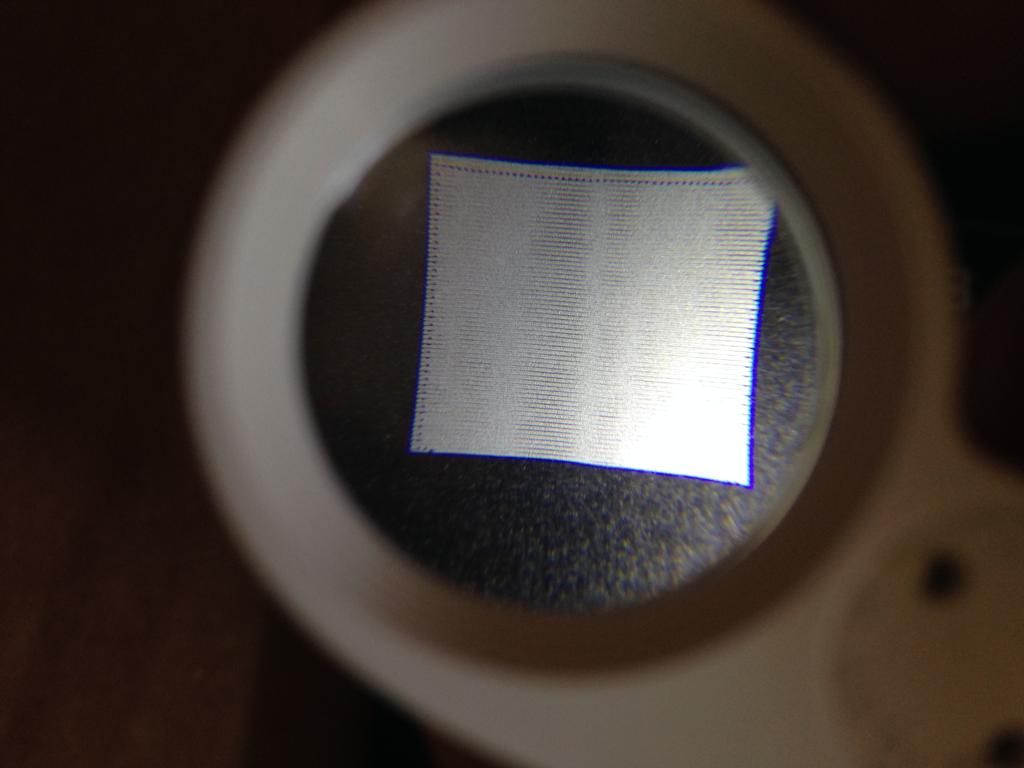

Here is the banding under the loupe

I engraved the same black filled square twice, one above the other but slightly displaced in the X axis. The banding appeared in the same location on the X axis, which again rules out the artwork and points to an issue with the laser, at certain points on high power settings the dot size appears to be fluctuating.

I know from searching this forum that these issues are rarely solved but I was hoping that having ruled out the artwork, there might be a narrower band of possible causes for the issue?

Cheers

Dan

Reply With Quote

Reply With Quote

)

)