I got out this pic for another thread, and didn't want to waste it.

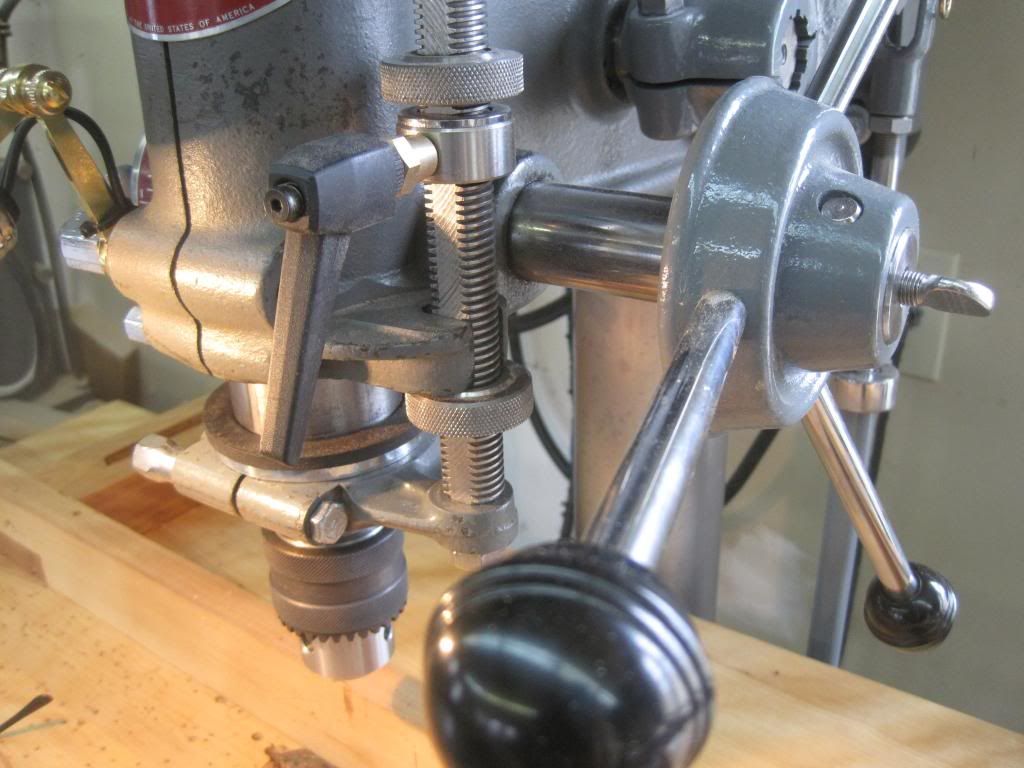

When you are drilling lots of holes at the same level, and don't want to adjust the table to that level, and you get tired of revolving the quill handle a couple turns for each hole........

use a simple clamp on the stop rod to keep the drill from going back up too much. Of course, if you want to be more elegant...get another stop nut and keep it on the bottom side.

P9220003.jpg

Rick P

Reply With Quote

Reply With Quote