Originally Posted by

John Crawford

Looks great, I look forward to seeing the final design, so that I can steal from it some day.

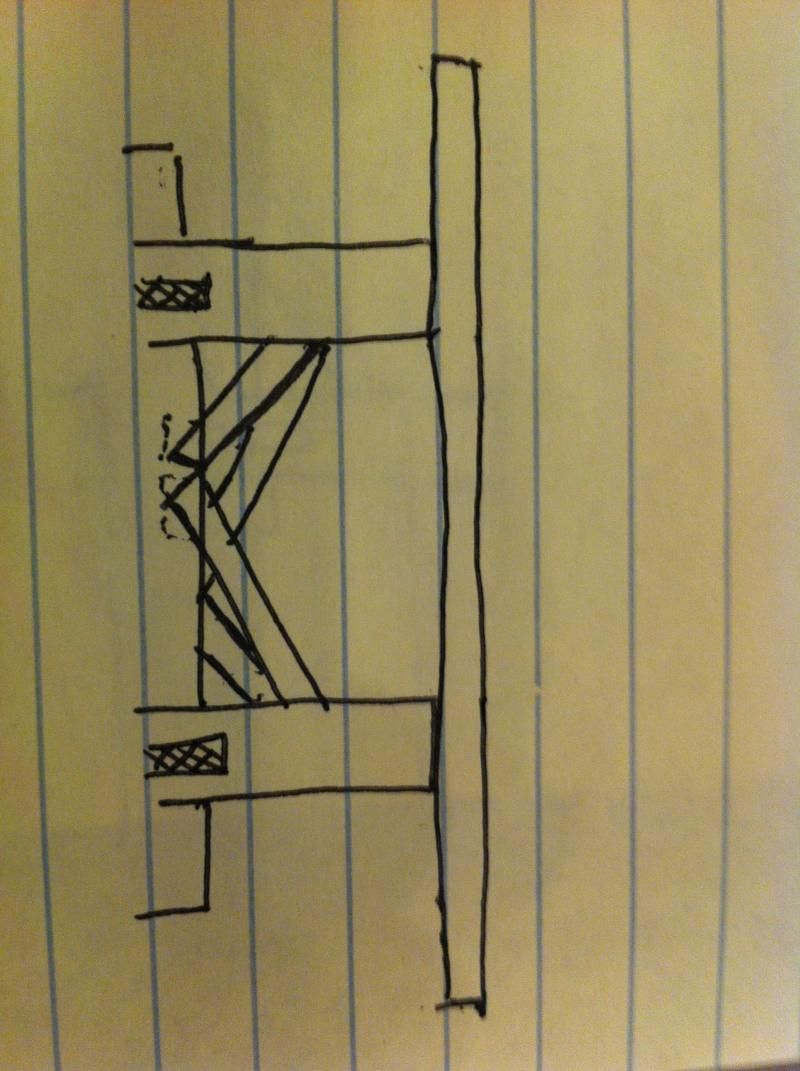

John, or anyone else, if you want a less elegant version of the same kind of saw bench Brian's making (a split top) you can click on my profile and look at the album "saw bench and plans" - pictures and plans, feel free to modify to your liking. Please just make a thread here and show us your saw bench.

Last edited by Judson Green; 12-18-2014 at 2:25 PM.

I got cash in my pocket. I got desire in my heart....

Reply With Quote

Reply With Quote