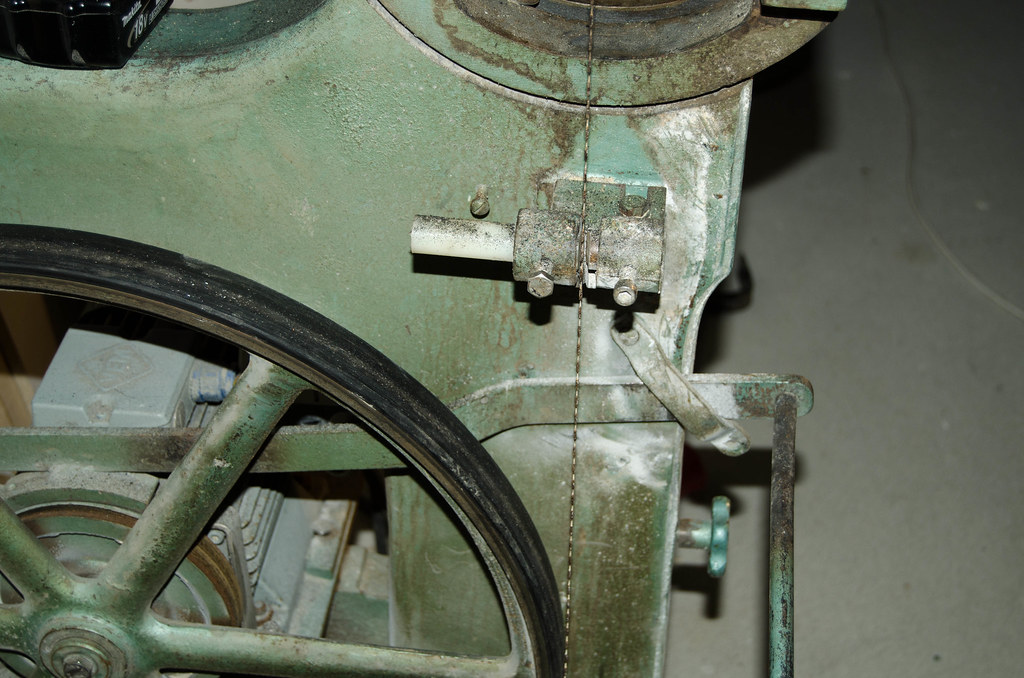

The lower blade guides on my saw are rather primitive to say the least:

There are only side guides and no thrust bearing on the back like most saws would have, even most vintage saws. The whole guide assembly is placed rather far down too in my opinion. Looking carefully at other designs it seems they have the lower assembly further up. It makes sense to me, the less distance between the upper and lower guides, the better tracking you ought to have, right? I'm thinking of trying to make a better set of guides from wood and mount on a riser block to get it closer to the underside of the table. The videos of Matthias Wandels bandsaw build has given me lots to go on when it comes to building one and it looks like a very simple construction. Question is if it's worth it?

Reply With Quote

Reply With Quote