If you guys haven't seen this, this looks like a great jig for those of use without dado stacks:

https://www.youtube.com/watch?v=JYxDXHGRRrk

It's been up a while but I haven't seen much said about it. I am currently half way through building this, I was going to build the Matthias Wandel box joint jig, but this one looks way simpler to build and I really like the cam idea. I also only really have one blade to cut with so I don't think I need different gear ratios. My blade is 3mm wide and with an M10 thread I get 1.5mm advancement per turn, so half my blade. That's a nice mathemtical setup.

There are comprehensive plans in the description, printed mine out and they are very helpful.

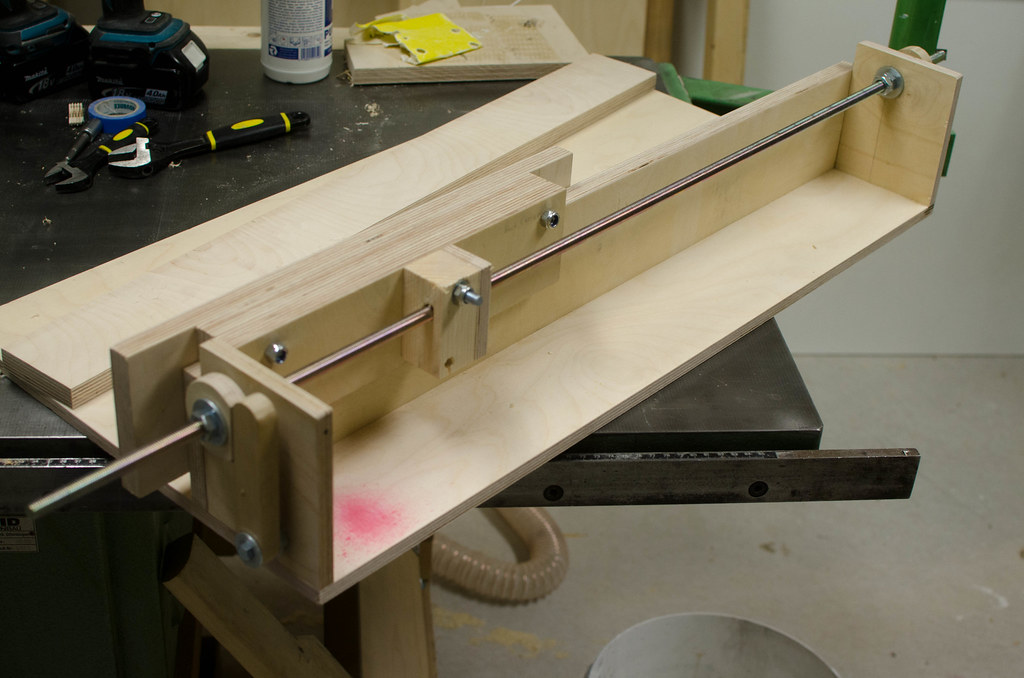

Here's what mine looks like so far:

Reply With Quote

Reply With Quote