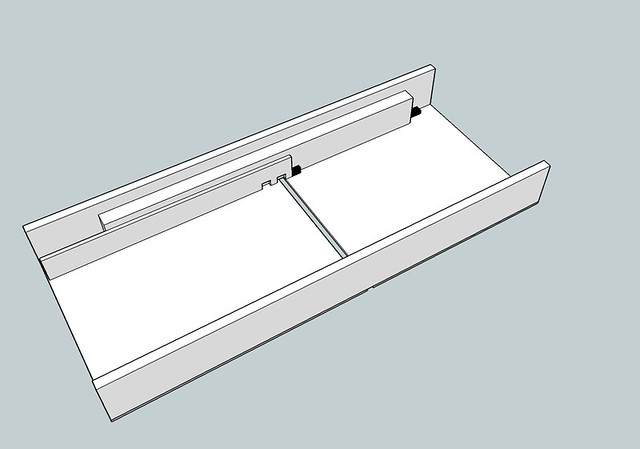

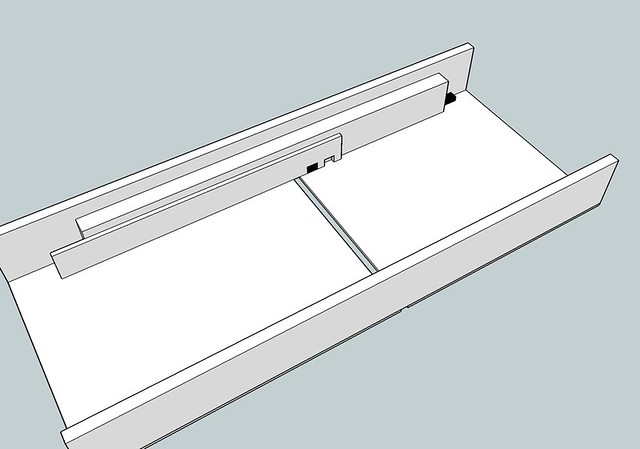

Hopefully this picture expains what I am trying to do. Each bar has 8 evenly spaced cuts. I have 20 of them to do. My dado will not cut the full width of the cut in one pass. I thought I had this figured out but when I went to do it I failed. I scratched my head for about 2 hours and made lots of test cuts but I could not come up with anything. I also have a router table I can utilize but only one miter guage.

Reply With Quote

Reply With Quote