Originally Posted by

Derek Cohen

Sorry Steve, but we are not on the same path this time. I think it may be terminology (some refer to a secondary as a micro, and vice versa - I do not).

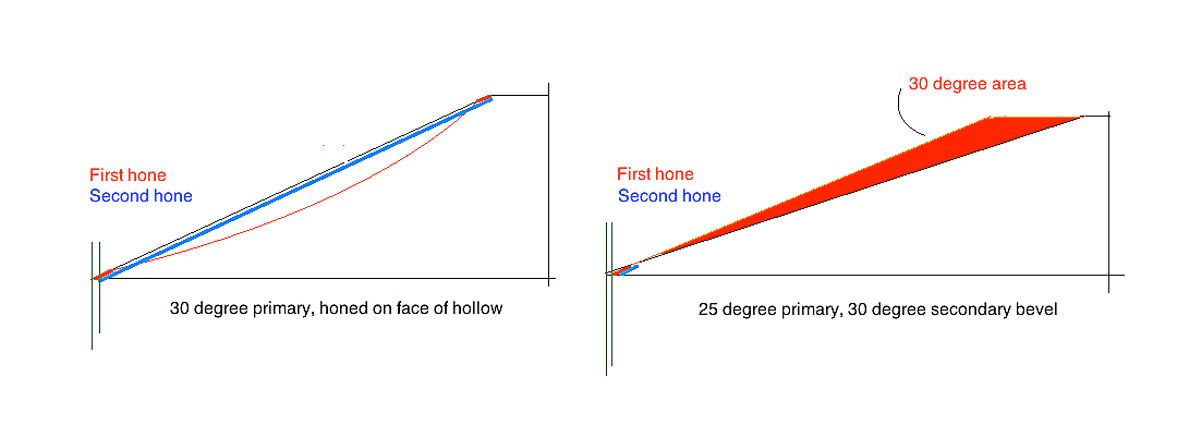

Firstly, a coplanar grind/hone simply means "in a straight line", or "in the same plane". Therefore, when you hone directly on the surface, a 30 degree primary bevel produces a 30 degree cutting edge. There is no secondary bevel. Get the hollow close to the front of the blade, and you will have a coplanar micro (small) bevel.

No one has mentioned which method requires more or less strokes. You introduced that. In this light, you suggested lifting the wear, which would create a secondary bevel. I did not suggest this. I am referring only to honing on the hollow (which creates a coplanar bevel face). As I noted before, this is essentially the same as honing on a flat bevel, but with a much reduced amount of steel to hone. Only in this regard do I mention speed, which is faster with the hollow vs the flat. I am not including the secondary hone here, which can be as fast or even faster to do, but not as easy to re-do.

Regards from Perth

Derek

Derek, I'm more than happy to drop this, but just a couple clarifications first.

I know what coplanar means…I used to teach math, you know.  But you are missing my point. Your hollow grind (in your first diagram above) is an arc, and so by definition does not have a fixed angle. If it did, we'd have no use for calculus! Look at your diagram and draw a tangent line to the arc, right in the center of the arc. That line is parallel to to your "coplanar bevel," and so has the same angle. But if you draw the tangent line at the bottom of the arc, where the cutting edge actually is, that tangent line has a considerably shallower angle than your coplanar bevel. Conversely, at the top of the arc, the tangent line is steeper than your coplanar bevel. There is no such thing as "get the hollow close to the front"--the hollow is always in the center, it can't be any place else, unless you are not grinding away all of the old bevel. No matter how steep or shallow your hollow grind is, when you balance that hollow on your stone and hone, you will steepen the angle at the cutting edge, and reduce the angle at the heel of the bevel. That is why your coplanar bevel is in fact a secondary bevel.

But you are missing my point. Your hollow grind (in your first diagram above) is an arc, and so by definition does not have a fixed angle. If it did, we'd have no use for calculus! Look at your diagram and draw a tangent line to the arc, right in the center of the arc. That line is parallel to to your "coplanar bevel," and so has the same angle. But if you draw the tangent line at the bottom of the arc, where the cutting edge actually is, that tangent line has a considerably shallower angle than your coplanar bevel. Conversely, at the top of the arc, the tangent line is steeper than your coplanar bevel. There is no such thing as "get the hollow close to the front"--the hollow is always in the center, it can't be any place else, unless you are not grinding away all of the old bevel. No matter how steep or shallow your hollow grind is, when you balance that hollow on your stone and hone, you will steepen the angle at the cutting edge, and reduce the angle at the heel of the bevel. That is why your coplanar bevel is in fact a secondary bevel.

Also, just to be clear, the reason I brought up lifting the back of the blade is that it was implied in your second diagram. I thought that was your intent, that the first diagram shows honing by balancing on the hollow, while your second diagram shows registering on a flat (could've been a hollow also) and then lifting the back of the blade.

This is making my head hurt. I'd have that beer now, but I already drank some of Graham's cider, er, scrumpy.

"For me, chairs and chairmaking are a means to an end. My real goal is to spend my days in a quiet, dustless shop doing hand work on an object that is beautiful, useful and fun to make." --Peter Galbert

Reply With Quote

Reply With Quote

. Most importantly you seem to be doing great and getting good results, keep doing it!

. Most importantly you seem to be doing great and getting good results, keep doing it!