Originally Posted by

Derek Cohen

OK Haydon .. have you had your meds today? A soothing hot bath?

I think I see what may be confusing you. I did not include it as it was too obvious. "Obviously" not!

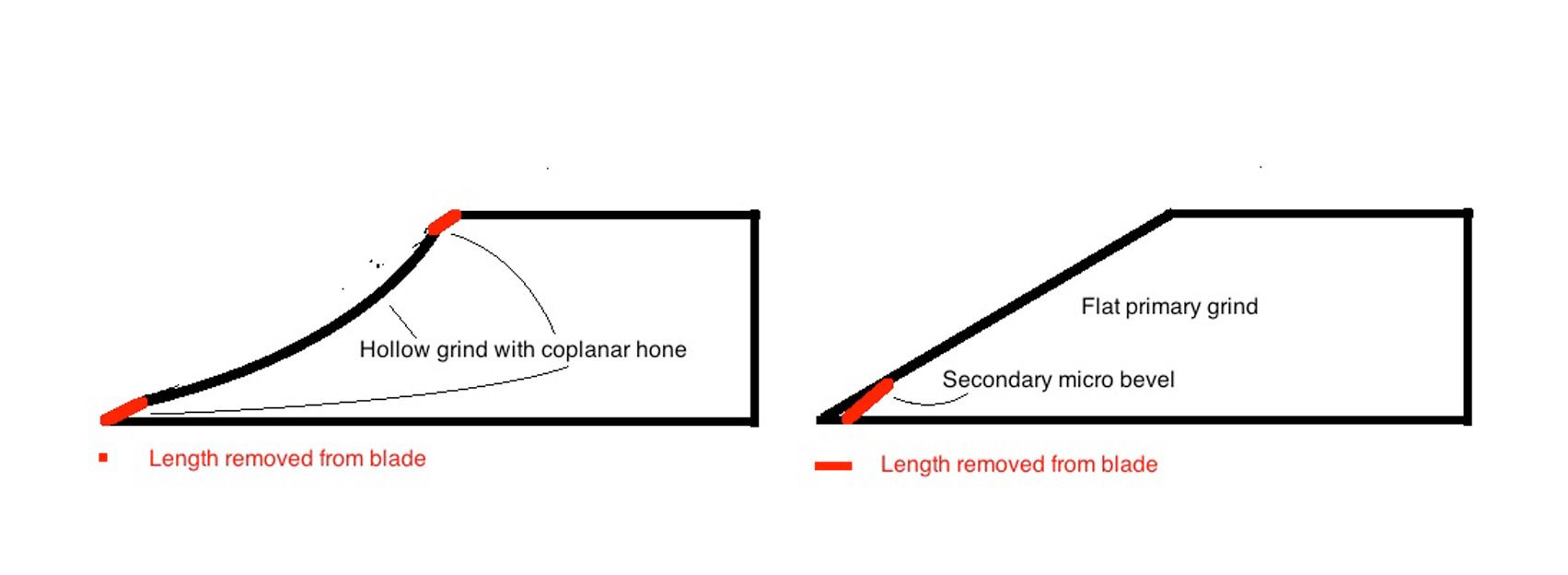

The primary bevel for the hollow grind is higher than the flat grind-plus-secondary to achieve the same cutting angles. For example, the primary for the hollow may be at 30 degrees, while the flat grind may be 25 degrees and the secondary on it at 30 degrees.

Adding that secondary will shorten the blade.

Regards from Perth

Derek

I don't think Graham is the one who is confused. Your argument is a little like Xeno's paradoxes, where one concludes that the arrow never reaches its target.

As he said, we need to work back a certain distance from the cutting edge, as measured along the back of the blade, to remove damage (or wear), whether it's damage from the grinding wheel or from work. Let's say that distance is .001". We then need to hone until the blade has been effectively shortened by .001. It doesn't matter whether we balance on the hollow or lift the blade off the hollow.

Since balancing on the hollow more closely approximates the initial grind angle, it will take more strokes to remove the wear than if you lift the blade. Perhaps that is what you really mean, that given an equivalent number of strokes, balancing on the hollow will remove less length? But of course we don't use an equivalent number of strokes. Balancing on the hollow requires significantly more strokes than lifting the blade does (I'm not saying one is better, just that one requires fewer strokes).

One other point. Both of the honed bevels in your diagram are "secondary" bevels. In your first diagram, if you draw a tangent line to the arc, right at the cutting edge, the slope is shallower than the honed bevel. It doesn't matter whether the honed bevel is "co-planar," it's still steeper than the ground bevel, and therefore meets your definition of a secondary bevel. Lifting the blade just produces a slightly steeper secondary method than yours.

Last edited by Steve Voigt; 04-25-2015 at 11:03 AM.

Reason: arc, not radius.

"For me, chairs and chairmaking are a means to an end. My real goal is to spend my days in a quiet, dustless shop doing hand work on an object that is beautiful, useful and fun to make." --Peter Galbert

Reply With Quote

Reply With Quote