I have settings that have worked great for rasterizing images on this 2-tone acrylic on the left side where I've been doing tests, but now that I'm using the full 24" bed for production, I'm seeing terrible performance on the right side.

This is on a new machine, under 2 months old with little use yet. These settings were 75% speed 35% power, which worked great on the left... I lowered it way down to 30% speed and 17% power and got much better results, but it is just so slow that way! And since I got perfect results with the other settings on the left, it's confusing.

Pics are below. Possible problems I think are:

1. My settings

2. Bed not being flat (but it's new?)

3. Laser not being aligned (but it's new?)

I've got instructions on how to check the second two, I just find it really odd that settings which work great on the left yield these results on the right. Each image is rotated 90 degrees so "left" is up.

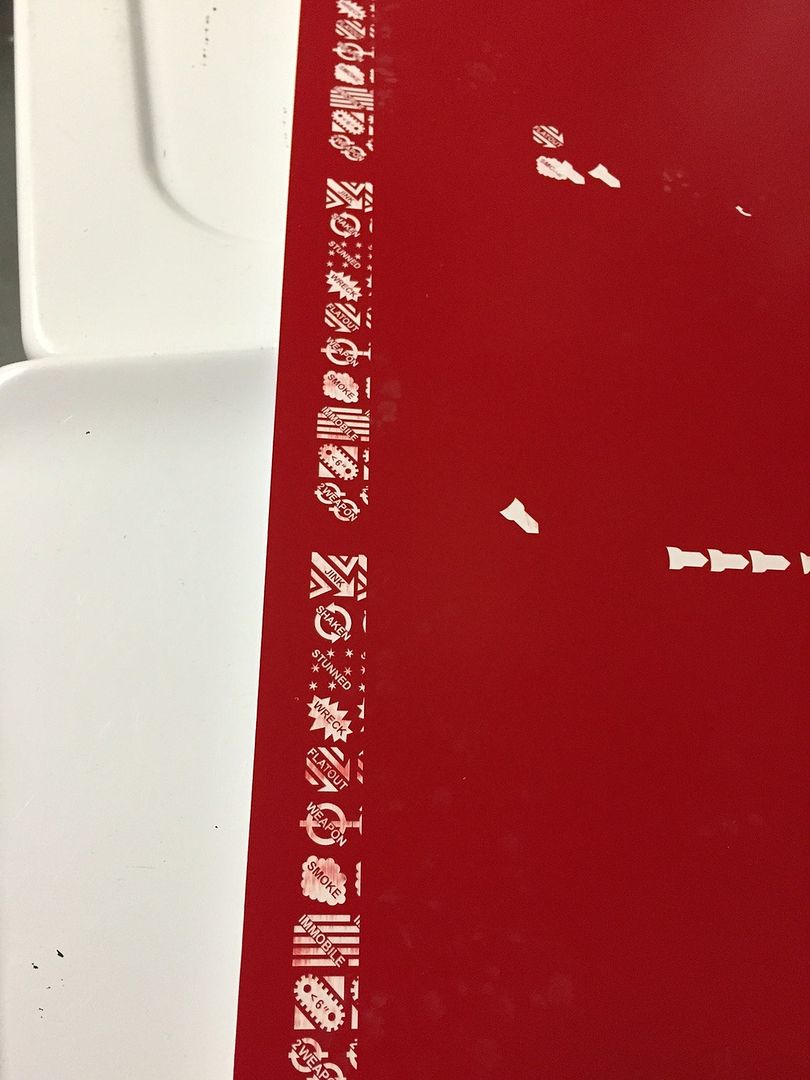

Image showing the left side (top of image) looks good, but the right side (bottom of image) does not:

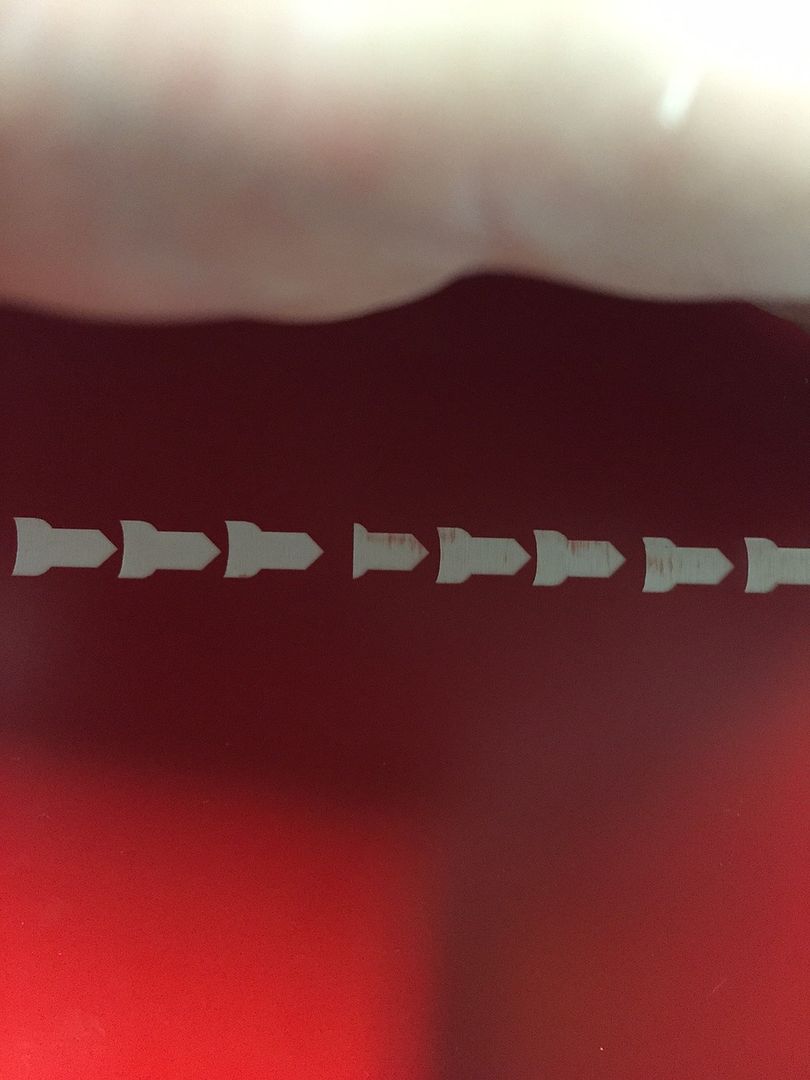

Image showing some things cut on the right side at different settings, only reallly slow seems to yield good results, whereas on the left faster settings gave good results (keeping the power proportional either way):

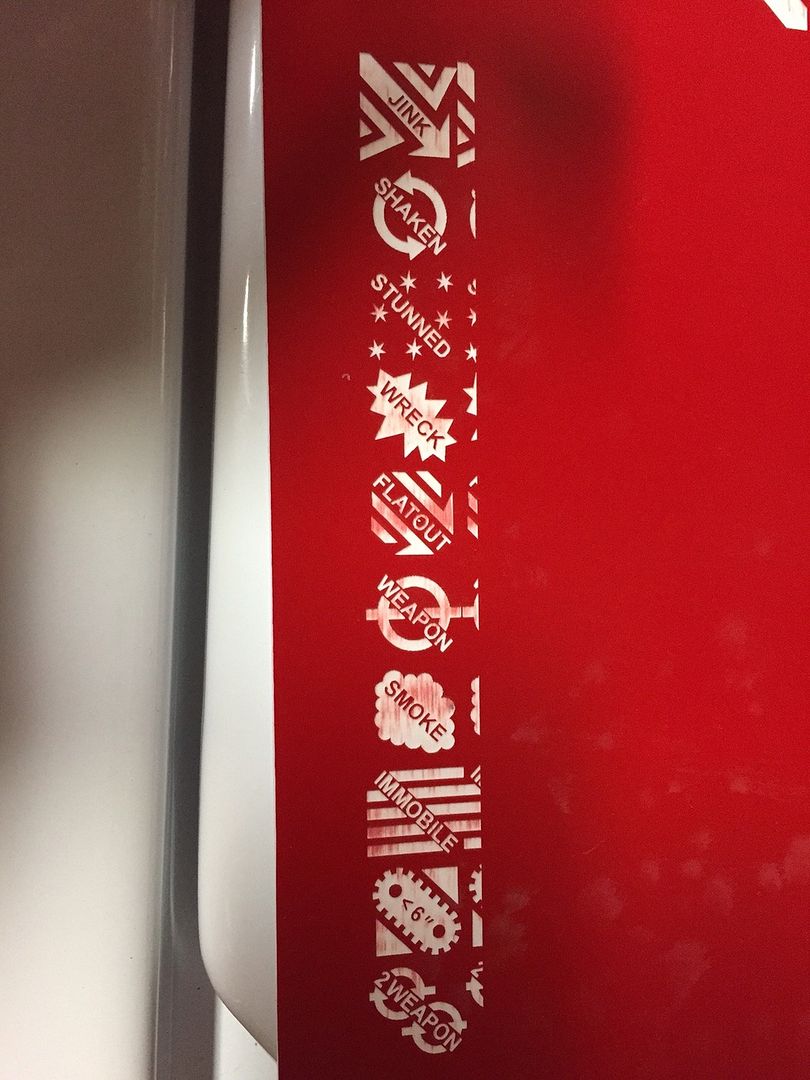

Image showing the issues I'm having on the right side:

Thanks for any assistance, let me know if you think it's 1) Settings 2) Bed flatness or 3) Laser alignment, and I'll get to bug checking!

Reply With Quote

Reply With Quote