[IMG][/IMG]

as the little sign in the shop window says, i did est my business in 1975 and I do work out of a commercial outlet by myself. did have 3 employees and I believe that I let them all go in early 1980. the work wasn't getting done that I wanted done and I despise comebacks. repairs are the main part of what I do. so in 40 years I have repaired quite a few chairs so you understand what has to be done to them so that you and the customer are happy and they don't come back. for adhesives I usually use hide glue. I have always used it and get it 5lbs at a time. if a chair comes in for being loose; it gets completely taken apart and reassembled. all dowells if so it is so equipped get removed and replaced. the other problem today is buying dowells that are up to size so i end up making most of them. Mike stated that I commented, " if your joint is "perfect" it doesn't much matter what glue you use" m but I didn't say that. What I said is, "epoxy is no better than any other adhesive if the joint is made and executed properly, but turns the item into a throw away in case of failure". if you make a joint that is loose you are doomed for failure sooner or later; most likely sooner

people use epoxy because mostly it is quicker and less work. there is a suposedly good millworking shop down the street that make wonderful looking fir exterior doors, when they make them though they leave a 1/16" inch gap at the tenons and fill the spaces full of epoxy upon assembly. they are laid up on a good flat surface so that everything just seems to float level and done. these doors are expensive and if there is ever a problem with them you just replace them.

most PVA glue joint can be loosened by injecting vinegar into them and let sit for awhile. you may have to refesh the vinegar a few times. I also but syringes and needles by the box. you just drill in with a .060" drill bit and put the vinegar in. if you require really fine needles; one of my old Chesapeake Bay Retrievers was diabetic and I saved all of her needles.

to me using epoxy to put chairs together is like having to wear a belt and suspenders at the same time. I don't mean to offend anyone by this. I do get enough chairs and that brought in by previous repairs where epoxy has been used and asked to save the piece afterwards.

here is one of my chairs and they do help in slowing down the racking problem. this one was made in 84 and customer4 still has in use every day

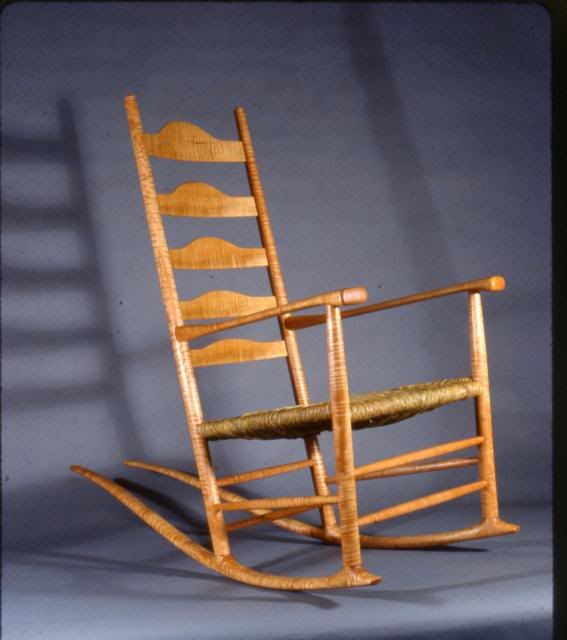

and this was a rocking chair that I made for the 1st AAW exhibition at the San Antonio Museum of Art a few years back

ron

Reply With Quote

Reply With Quote