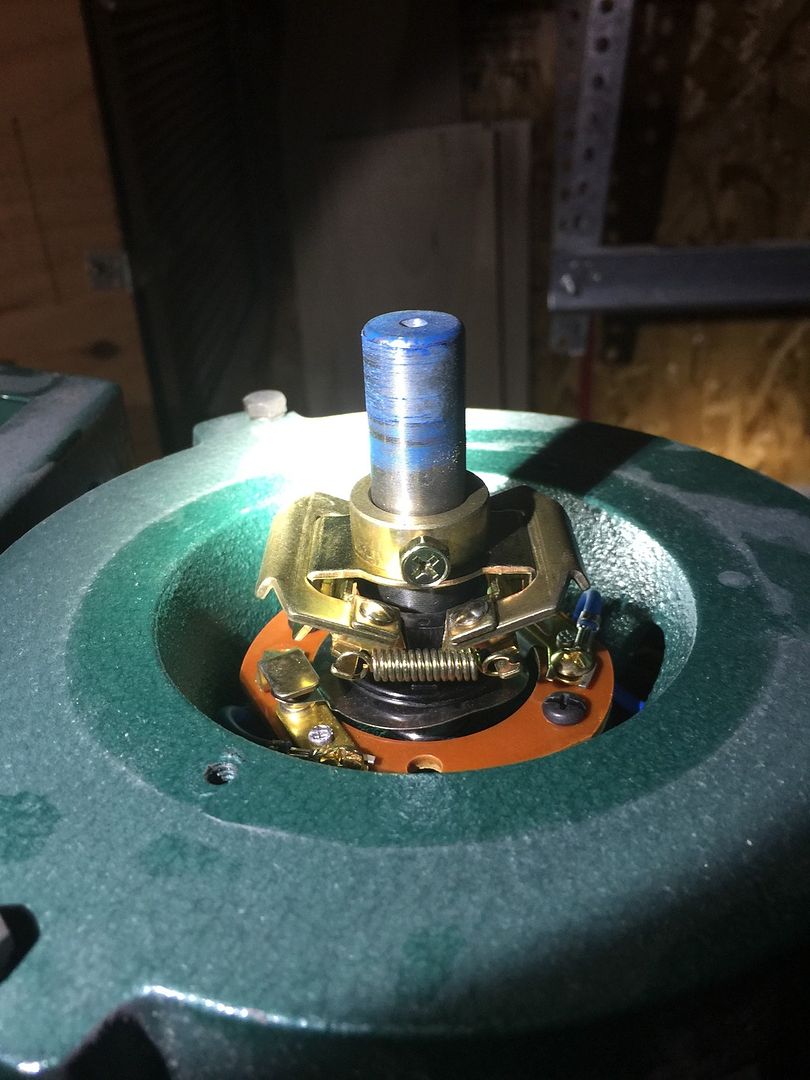

Not exactly sure what happened, no pops or burning smells or anything. Took a break for lunch and came back out and the dust collector wouldn't fully turn on. I pressed the on button, it sounds like it's beginning to start then it flipped the breaker. Did some googling and I'm not entirely sure but it sounds like it could be a bad start capacitor?

Here's a video of the sound:

https://www.youtube.com/watch?v=H_HN...ature=youtu.be

Does this seem like a start capacitor? Any other troubleshooting steps before I test the actual capacitor?

Side note: If it is the start capacitor, what is a good manufacturer to replace with? I know the replacement is 300mfd/125VAC but I don't want to replace it with a cheap one so I can hopefully avoid replacing down the line.

Lastly, I run my dust collector in my garage (someday I'll have it outside) and I turn it on/off kind of frequently since I don't need it running while I'm not cutting. I've read a few people post that motors like these should not be started/stopped often. Is this correct? If so, what's the number of stops/starts per hour you should try and stay under?

Reply With Quote

Reply With Quote