Hi everyone,

Over the past year, after stumbling onto Tom Fidgen's website and books, I've been doing a lot more work with hand tools and loving it. I have a project coming up that I want to use all hand tools on (it's a small spice box). I needed a pair of book matched veneer for the door. I have a nice peace of walnut that I was planning to saw into veneer. The question I have is how to plane one side of such a thin peace of stock after it has been cut into veneer?

Say I have a board that has been planed on all four sides, I then saw a peace of veneer off. No problem I can glue it to the panel and plane the saw marks off. The problem comes when I want to saw a book matched peace. You see I can again plane all four sides of the board and saw another peace of veneer, but the side with the saw marks on it will be the side that needs to be glued down. So with such a thin peace, what's the best way to remove the saw marks? Remember I'm using only hand tools on this project.

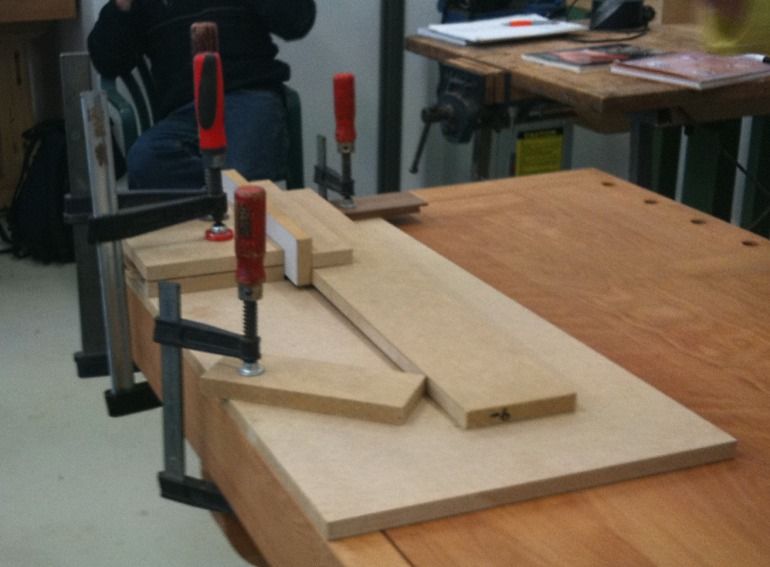

One thing I thought of doing was using hide glue to glue the peach down to a board, plane the saw marks out, then use a heat gun to loosen the hide glue and remove the veneer. What do you all think?

Reply With Quote

Reply With Quote