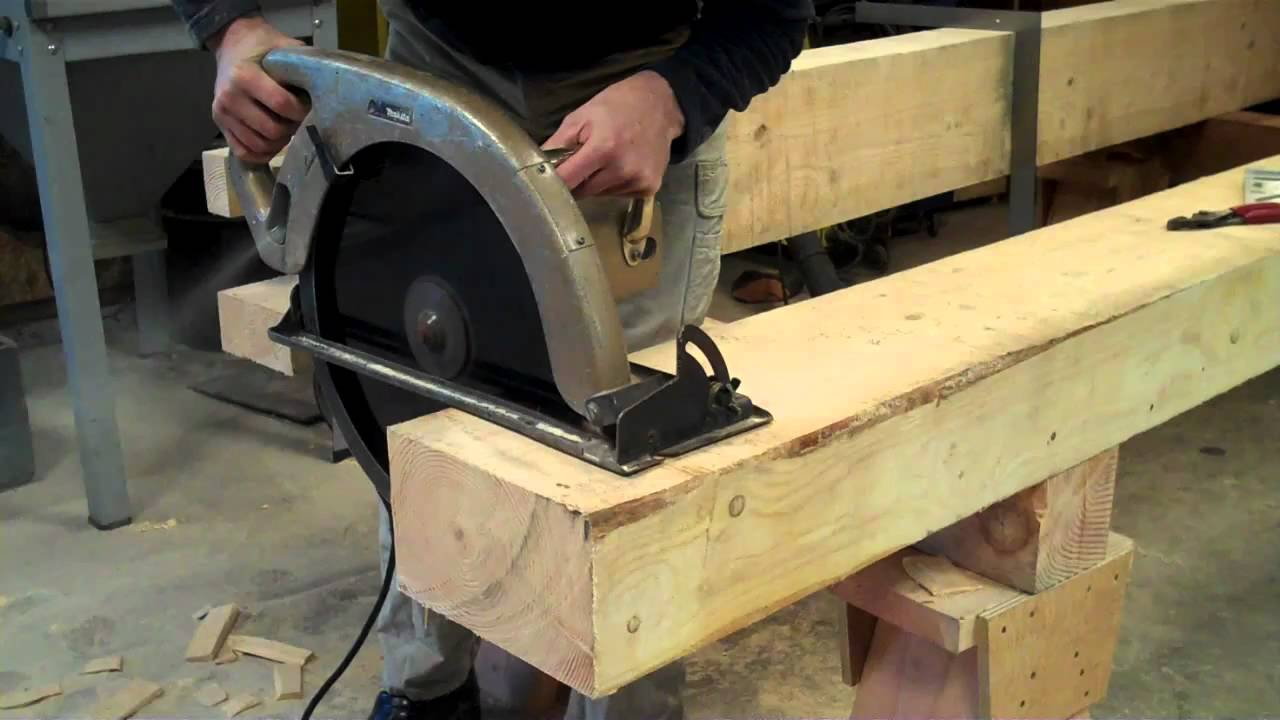

Thanks for all the quick replies. We will first try to rent a larger circular saw if that cannot be done then we will cut as deep as possible with our saw (I have an E-Z guide so I can get a straight square cut). The use a hand saw to show the kerf on the opposite side, then clamp up the E-Z Guide and cut from that side. It will be awhile before we do this since we are flattening with hand planes.

Reply With Quote

Reply With Quote

) If you can first run that stock through a planer, then no problem, but I'm assuming you don't own a 40" wide planer.

) If you can first run that stock through a planer, then no problem, but I'm assuming you don't own a 40" wide planer.