Originally Posted by

Derek Cohen

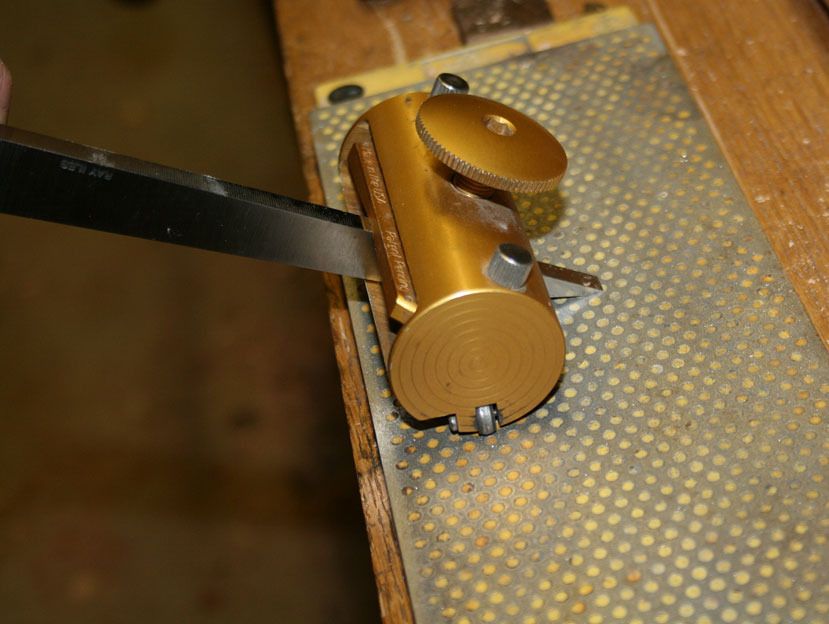

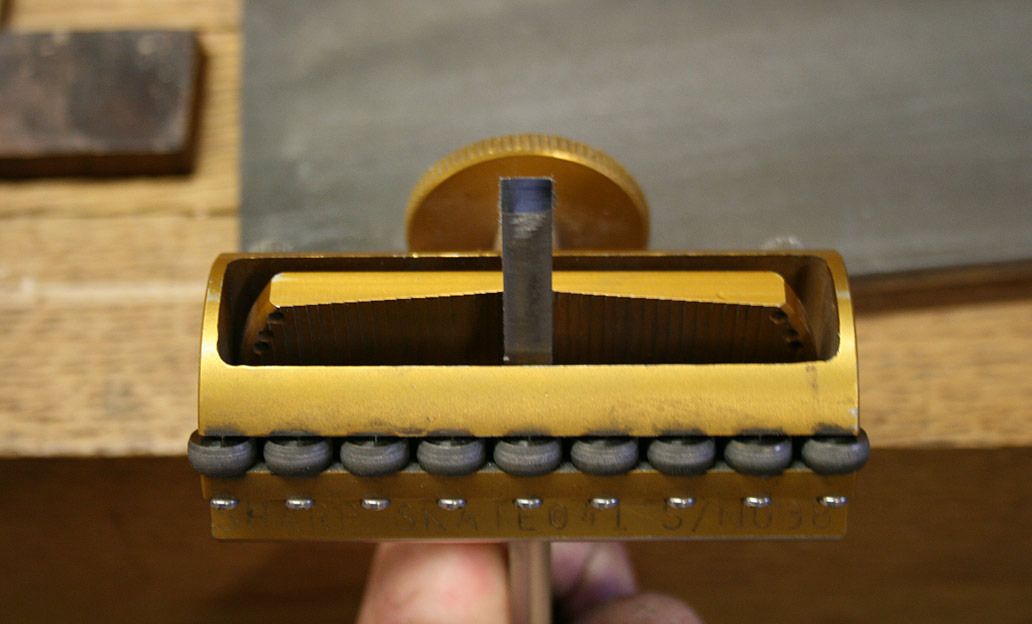

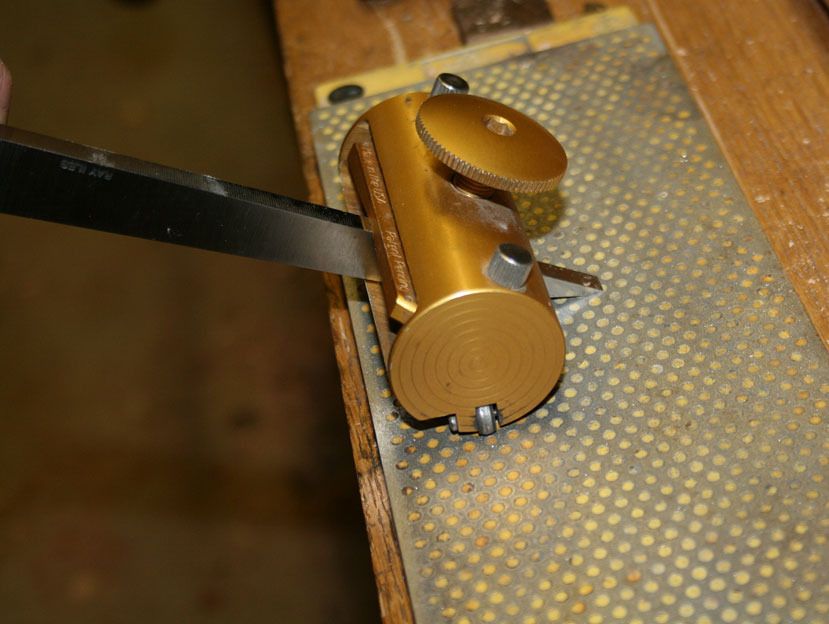

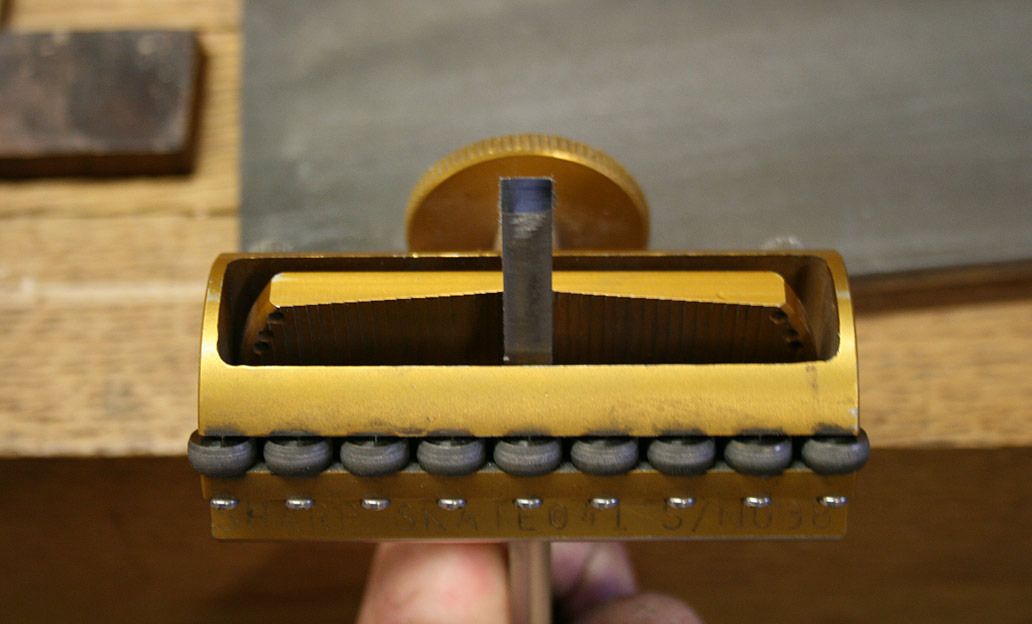

The very best honing guide for mortice chisels and Japanese chisels - it was designed with Japanese chisels in mind - is the Sharp Skate. this is a side sharpening guide designed by Harrelson Stanley.

Absolutely secure with deep mortice chisels.

Regards from Perth

Derek

Originally Posted by

Derek Cohen

Hi Brian

The Kell #1 is too narrow for wider bench chisels. I bought it for mortice chisels. It sucks - difficult to hold and difficult to determine the angle.

The only chisels I use a guide on are mortice chisels. Otherwise I freehand everything.

Regards from Perth

Derek

Thanks Derek!

Bumbling forward into the unknown.

Reply With Quote

Reply With Quote