I’m moving my 2HP Grizzly GO440(1354 CFM) Cyclone DC from inside my heated shop to another portion of my garage that is not heated during our cold Indiana winters. My ducting main is 6” reduced from the 7” cyclone intake. The reducer is attached directly to the DC intake.

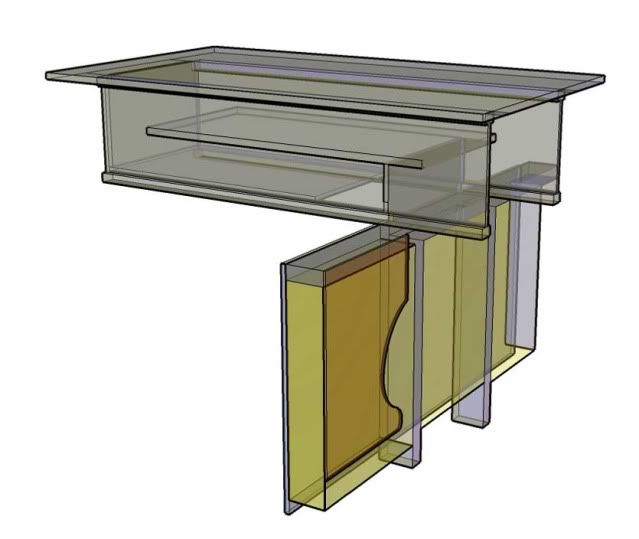

I intend to build a closet surrounding the DC. The closet enclosure will be constructed as air tight as possible. One reason is noise suppression and the second being to be able to get the heated air returned to my shop as efficiently as possible. For this second purpose I am proposing to install flexible insulated ducting in the ceiling of the closet that will pass thru the unheated garage attic space and be returned to my shop area.

Simply put the DC will suck the (heated) air into the closet space and being an air tight area, once the closet becomes pressurized, the air will then be naturally “forced” into the return ducting back into the shop area.

Is there a formula to follow to figure the proper size return ducting? I will have the return ducting runs at least 15 feet long to minimize noise transfer. I’m guessing that since the incoming closet air is forced in via the DC and the outgoing flow is unforced, I’m going to need significantly larger return ducting over the 7” inlet size. So will two 8” return runs be sufficient? How about one 12” run or two 10" runs? Any help would be much appreciated, thanks!

Reply With Quote

Reply With Quote