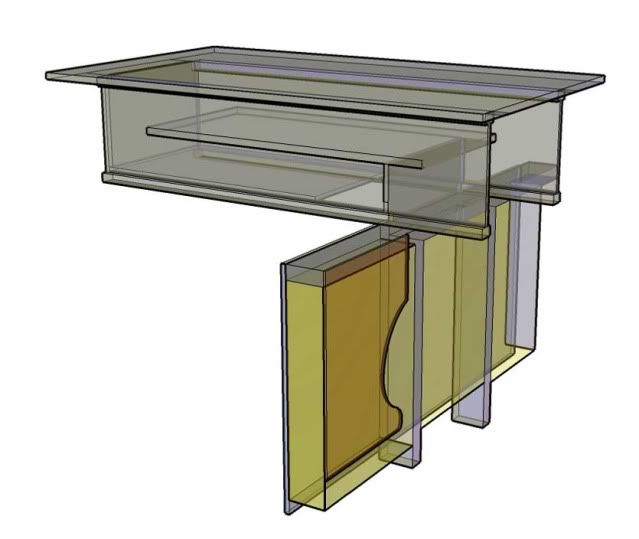

My DC closet uses a return baffle in the ceiling (between joists) and amounts to about 8' total (4' folded). (see illustration below) The inside of the closet has unfaced fiberglass insulation in 2x4 walls with 1/4" Masonite perf-board with the rough side exposed. This has worked out very well to contain noise from both my cyclone and my compressor.

Reply With Quote

Reply With Quote

. Thanks.

. Thanks.