Got around to cleaning up and tuning up some hand planes this weekend.

Still need to file down the mouth of the No. 6 since the new Veritas blade and breaker are too thick.

The No.4 is a Type 10 and the No. 6 is a Type 9. I like a Type 10 better since it has a frog adjustment screw.

No.4 Type 10 before clean up. Ninja the Doberman wanted to help...

After

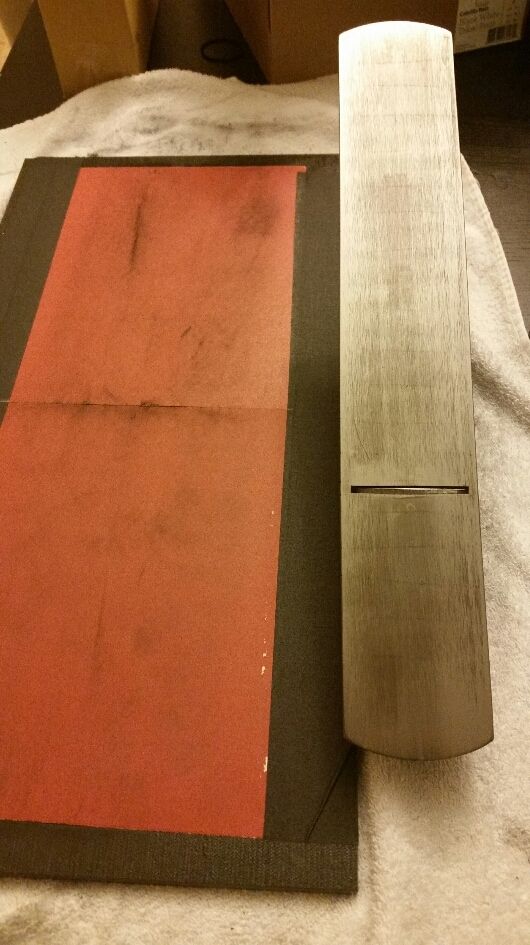

Before Flattening (No. 4)

After. Some of the pitting remains but would probably need a regrind to remove it all. (No.4)

No. 6 Before

After

On filing the mouth down, I just used a sharpie for my reference line. Is this too much material to take off at one time? about 1/32 or so.

Reply With Quote

Reply With Quote