Does anyone use them? And, if so, what are your thoughts comparing them to dogs?

I'm speaking of the type that usually either knock up/down, or have some kind of screw mechanism, and usually have metal teeth. I don't see many people talking of them, or demonstrating their use, so I was curious.

The metal teeth seem to be a double-edged sword; I could see how they would be great for holding the wood down when dimensioning rough lumber, or before you've made your final cuts, but surely you don't want to mark up your work in many cases? I suppose you just put a small piece of wood in front of it when that's the case?

Does anyone still make/sell these? What styles are available, and what do they normally go for?

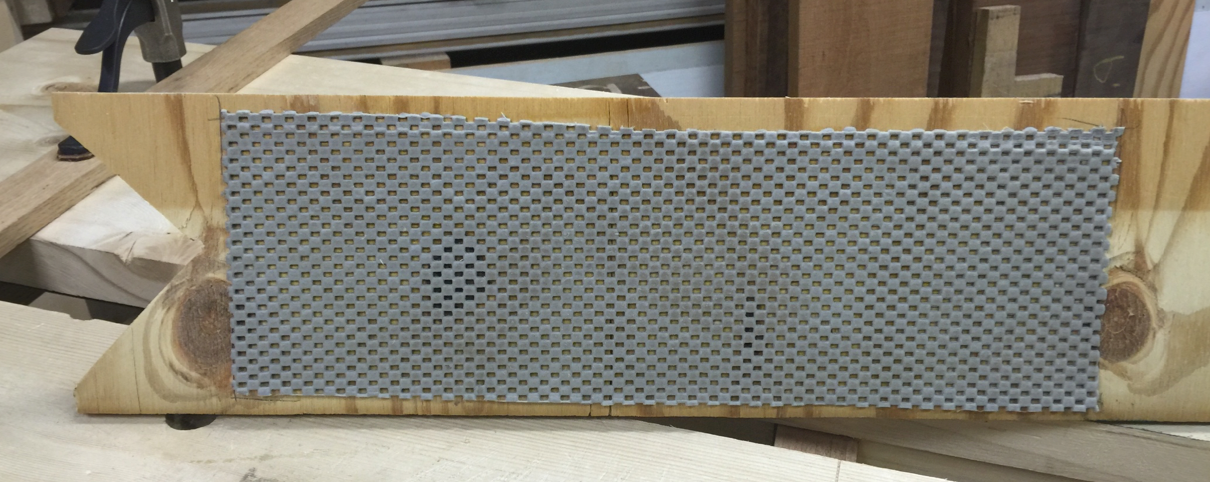

I'm deciding what to do with my bench, and I think I want to go with a very minimalist setup. I won't have an end vise, so an extensive dog system is not really necessary. I was thinking of just going with a few holes for my hold fast, a planing stop of some sort, and a small front vise. I have, of all things, a canvas hanger with teeth that looks like it would make a neat makeshift stop - I may just screw it to my benchtop temporarily to see if I like the concept and want to get a permanent one.

Reply With Quote

Reply With Quote