As I've mentioned previously, Professor Dr. SWMBO recently became a beekeeper and as you might expect, bee hives are made of wood. Since the weather was rainy this weekend, I decided to spend some time in the shop (landscaping work in the rain is NO fun!) and just for fun, build a couple of hive boxes. In general, there's little point in building them from scratch myself financially as knock down kit boxes with production box joints cost about $15 (with select pine) and my cost for common pine to do buy material for the same box is $12. So unless "free" material is involved, making these things is primarily a fun way to spend time in the shop. That said, I enjoyed the task so the fun part was covered.And I'm not ruling out making more in the future if needed just because it's pleasurable to do so, even though financially, there's little incentive.

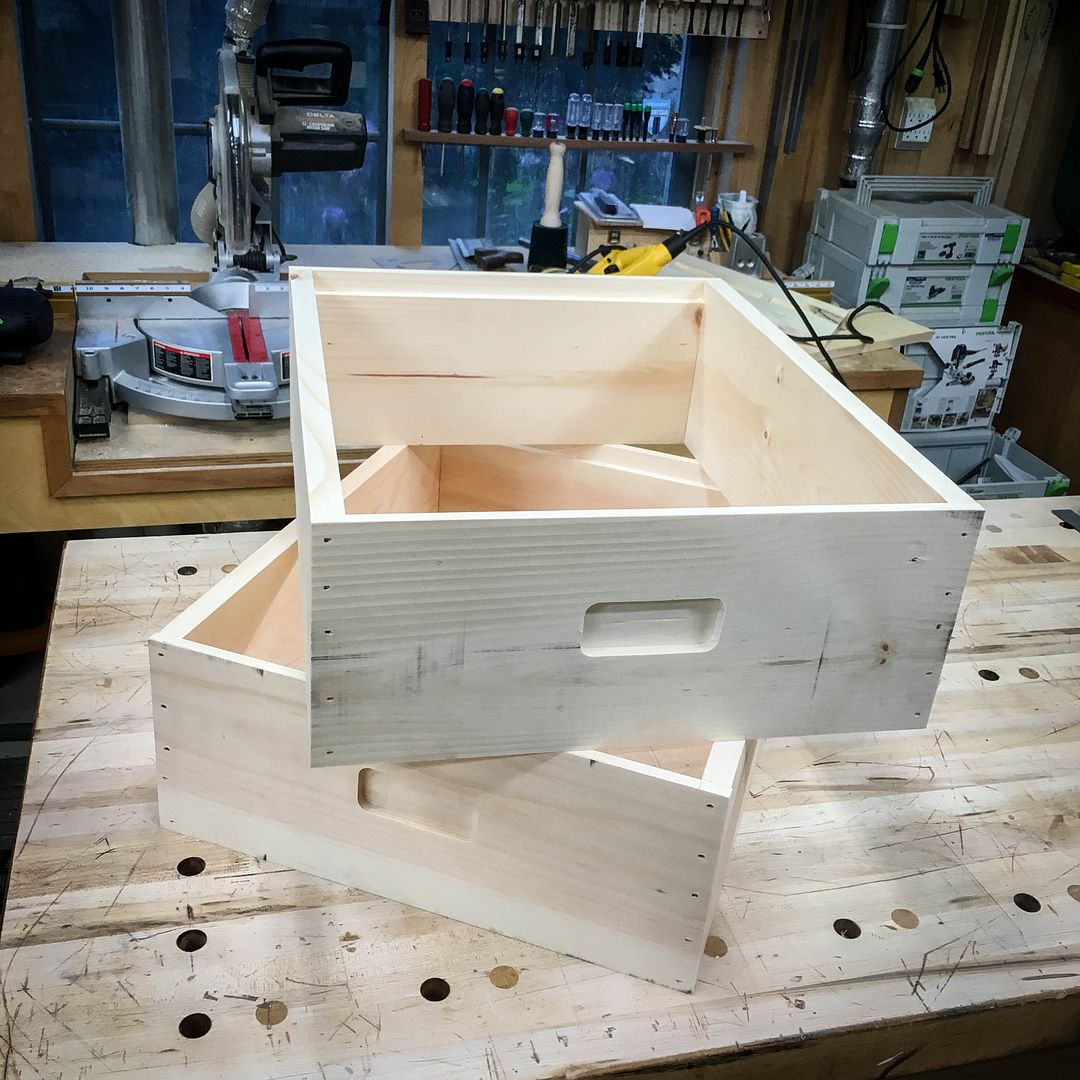

Ok, it's a box. Without a top or bottom.Really exciting, eh? But there's good things about simple projects and lessons to be learned from them, too. The ends have a rebate that the comb frames sit on. I'm not setup to do box joints and chose to use simple rabbit joints with glue and nails which is plenty sturdy for the job. Each of the two hive boxes (in this case, called "medium supers") came out of an 8' long 1x8 pine board. All four sides also get a hand-hold to make it easy to pick them up...they are quite heavy if the 10 comb frames they hold are filled with honey. And I'll mention now that those hand-holds need to be on the outside of the box...you'll see why in a moment.

I didn't bother to take photos of the four pieces of wood used to construct the box nor cutting of the rebates...all done on the sliding table saw. The rebates are all 3/8" deep and 3/4" wide and only appear on the box ends that hold the comb frames. You'll see that relationship post assembly. But in the meantime, there are those hand-holds. To accommodate that need, I made a template to use a router. Some folks use a sloped jig and a circular saw, but I didn't feel like building something like that for this quick rainy day project. The template is designed so that it's easy to center on both the shorter ends and the longer sides...the "fence" at the top is the length of the longer sides and the flat portion is the length of the shorter ends. This can also be used for hive boxes of any depth in the future, should I decide to make more.

The template is used with the router to cut the handholds...bit depth was 3/8".

Here are the components for one box and you can see how the rebates are setup on the box ends

Assembly is just by glue and 15 gage 1.5" nails from a gun while everything was locked square in parallel clamps

Remember I mentioned that lessons can be learned? In the "excitement" of assembly, I accidentally inverted one side (on EACH of the two boxes) and inadvertently ended up with the handhold on the inside of that piece. ("D'oh!!") Now I know why some of the folks who make their own hive boxes cut their handholds after assembly. LOL The fix was to use the template to cut an hand-hold in some scrap material, re-saw that to create a pattern that could be traced on a piece of 3/8" thick material and then cut out a patch to glue in place. Once that was in place, the template was used to re-cut that particular hand-hold in the correct side of the box side. Yea, "stuff happens", even with simple projects...

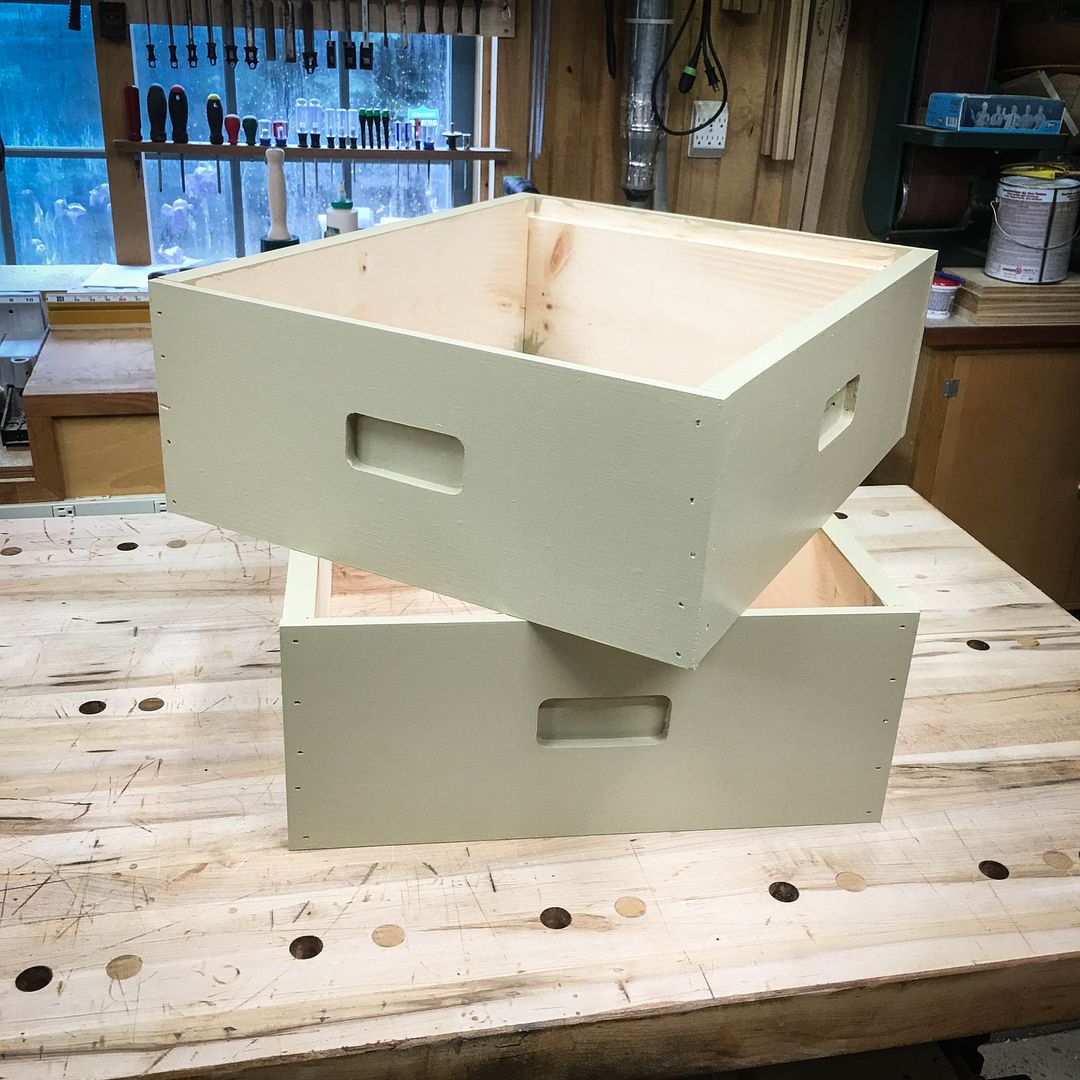

At the end of the day...a couple coats of paint went on and these are ready to be used in the future if and when they are needed.

And just so you can easily understand the function of the rebates if your'e not familiar with beekeeping, here's a photo of how the frames sit in a hive box

Reply With Quote

Reply With Quote