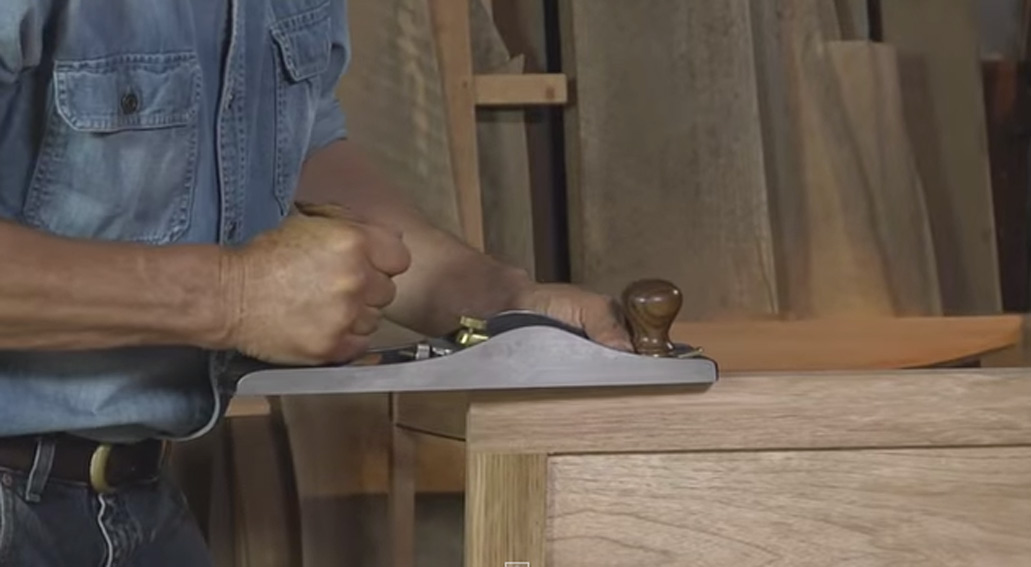

The basic stance looks better, but Warren's right - the cut is too aggressive and you're stopping/starting too much. Building upon my string of marginal sports analogies it looks a little like a weightlifter who's trying to put up more than they can cleanly lift, and "jerking" to make it work. Not coincidentally people who do that also get joint issues.

I also think Brian is probably onto something when he asks about camber - IIRC from other posts you don't camber your jack/scrub planes much if at all, and that means you're pushing a full-width shaving. That's a super difficult way to rough even with a narrow plane like a scrub. FWIW I mostly rough with 2" wide (#5, #5-1/4W) blades cambered at 6" to 12" radii. I almost never take a full-width shaving, and I back off if I end up stopping in the middle of a shaving. The nice thing about camber is that backing off the depth also reduces the width, which gives the adjustment a lot of "dynamic range" (large range of achievable shaving cross-sections).

It's hard to tell from videos but I suspect that I take significantly smaller shavings than you do. Size isn't everything :-).

Reply With Quote

Reply With Quote

I am glad to be the guinea pig this time.

I am glad to be the guinea pig this time.