Ask any apiarist (beekeeper) who makes their own woodenware (hive components), including those in our midst here at SMC, and they will tell you that the one thing they don't "make" themselves are the frames that go in the hive where the bees make comb. It's the one thing that most folks buy, either as unassembled "kits" or built and ready to use. The level of labor required for making them from scratch is huge...and I can attest to that personally based on this little project. Professor Dr. SWMBO buys them, too, but I decided that for "grins and giggles", I'd make up some from scratch as an exercise in thinking through a project with some interesting dimensional requirements and joinery. And coincidentally, we wanted a few that were different that the majority we use already for some particular purposes...these would be "foundationless"...meaning there is no pre-supplied surface of wax or plastic that defines the comb structure for the bees. They get to "roll their own" with these frames which sometimes has benefits.

This is a frame style with a pre-installed foundation for reference (from a supplier on-line catalog):

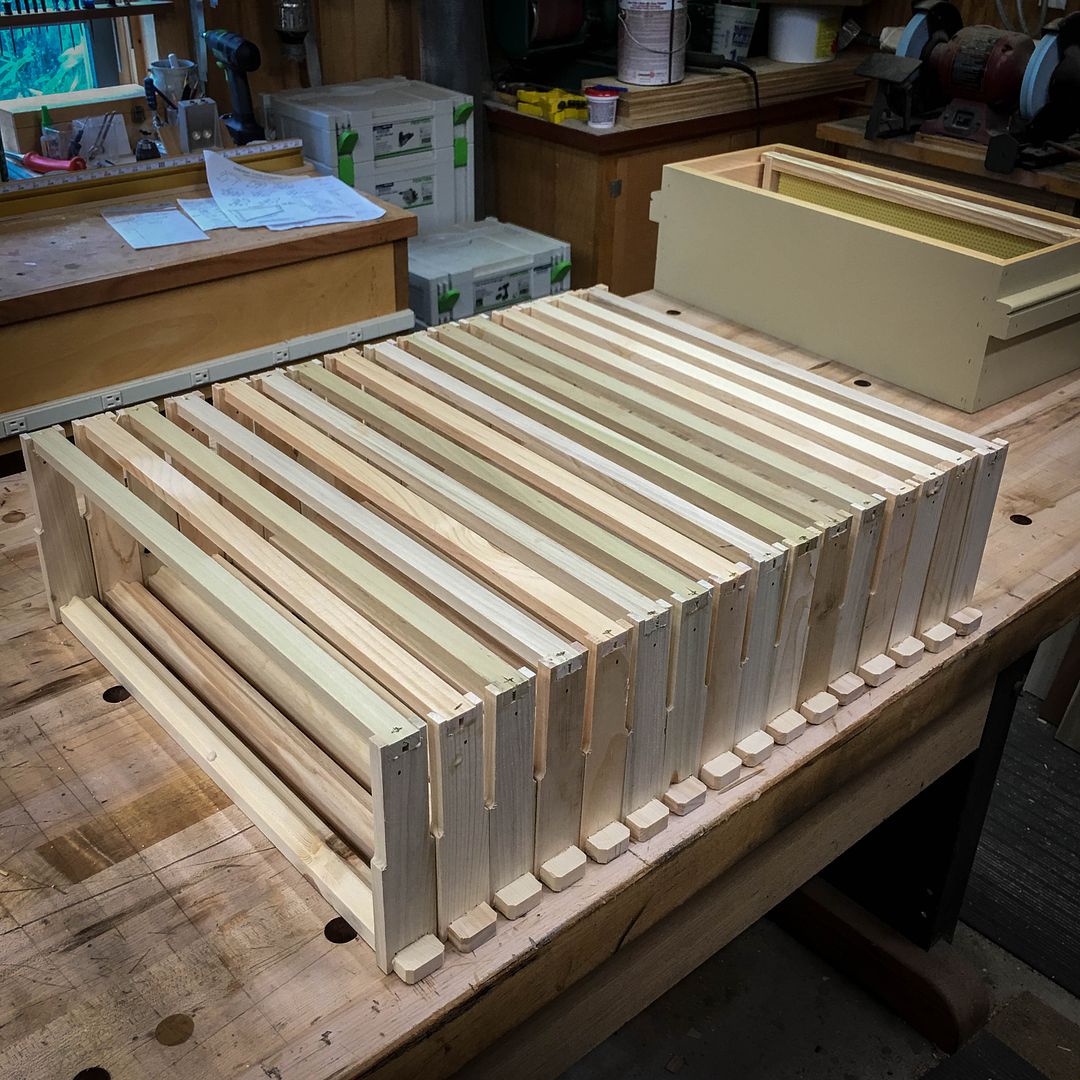

What I build here in this project looks like that, but doesn't have the yellow or black sheet of "foundation" installed; rather, there will be a milled feature on the underside of the top bar where the diligent bees (who are all girls, BTW) can easily attach natural comb. I'm creating a set of 16 of these frames and it also involves building some jigs.

These are the top bars for the frames. They start out at 3/4" thick and 1 1/16" wide. Using a 45º veining bit in the router table set 1/4" high from the table top, two passes were made off-set from the center to provide about a 1/16" wide flat spot with sloping sides on what will be the underside of the top bar.

That first step left material along the edges of the top bars that had to be removed...it was subsequently done by running the pieces along the saw fence with the blade raised just hight enough to clip off the excess material and leave those edges at about 1/2" thick. This is the end result for the profile:

Subsequent to that, a scoring cut was made using the miter bar to define material that would be removed to make the ends of the bar 1/2" thick:

Using a jig that holds the workpiece securely and provides a larger area for support, each end of the bars was trimmed to the scoring line with the resultant 1/2" thickness:

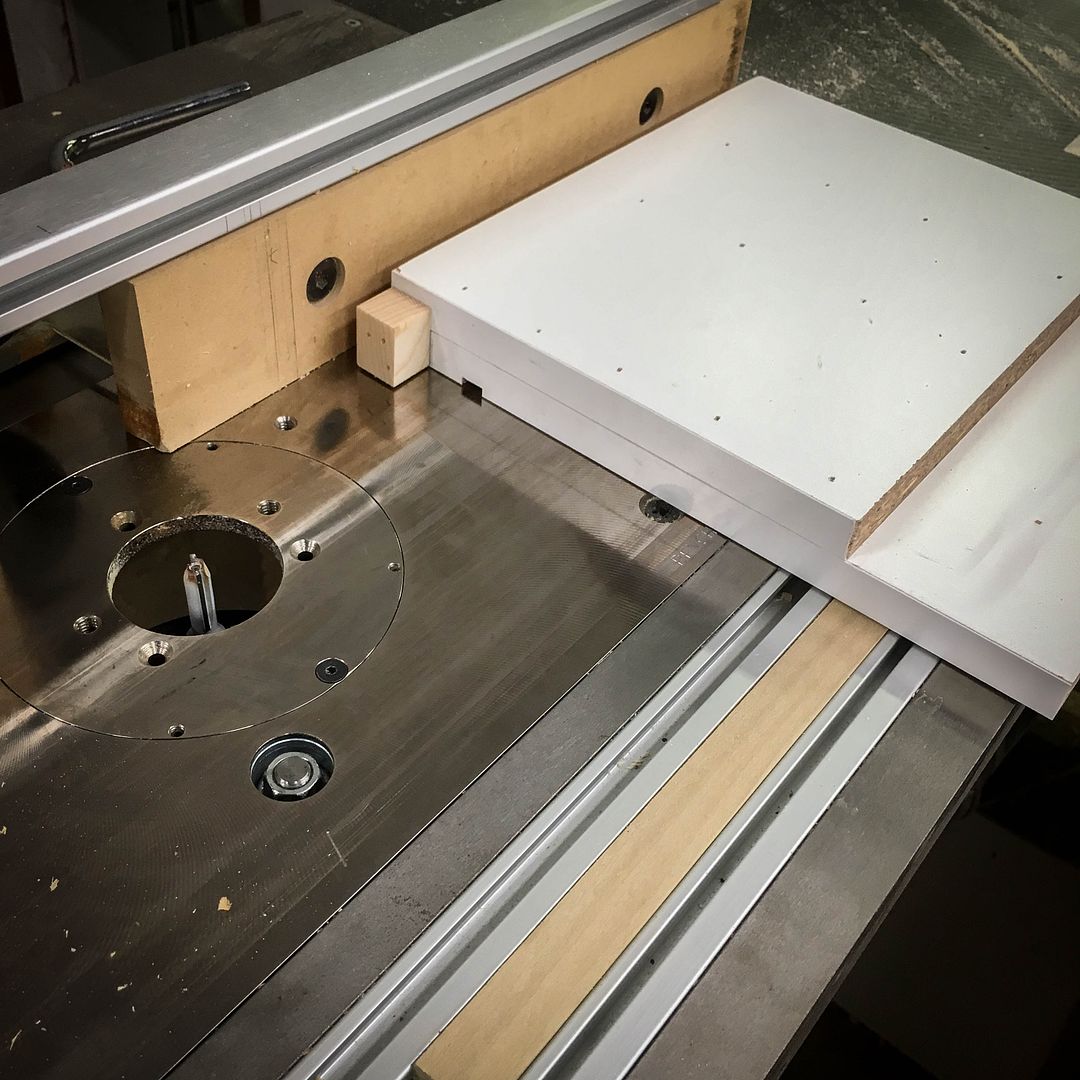

This is the jig used to allow a 3/8" wide by 3/32" deep groove to be place on the sides of the top bar to key in the end pieces that you'll see created in a bit. In all honesty, this was the one operation that I mistakenly did after milling the profile on the bottom of the bars...it would have been much easier to do this step first. I just wasn't thinking things through. Fortunately, there was enough material to keep the piece stable when the "pointy" profile was toward the jig fence:

The result from this operation is this:

Finally, to complete the top bars, the corners were knocked off at the miter saw in a two step process...45º angled right catches two opposing corners and then flipping to 45º left got the other two opposing corners. Stop blocks were set to make this a quick, repetitive and safe operation.

The end pieces needed to be notched to fit into both the top bar and to contain a bottom bar...so it was "build a jig time". These cuts define the width of the notches and are cut to the depth that the notches will be. This is the "top" notch which is wider so it can slip around the top bar while being contained by those small notches made in the top bar earlier at the router table

By moving the jig over an exact amount, a second slot could be cut to use for the notch definition for the "bottom" of the end pieces. Notations were made on the jig for the exact settings of the stops on my miter bar so this could be repeated in the future if I decided to abuse myself again and make more of these things...

At this point, there are 32 of those end pieces ready to have the notches cut out using a coping saw with the workpiece held in the bench vice. I marked the "bottom" ends of all of these on both sides with a simple black dot with a sharpie to be sure that there was no mixup with a later operation at the router table

Reply With Quote

Reply With Quote