Ok, now I am safely back at home: The German Schruphobel. (Or scrubplane).

ece42a.jpg

First a little bit of history. The German dictionary from 1714:

Curieuses und Reales Natur-, Kunst-, Berg-, Gewerck- und Handlungs-Lexicon.

They talk about the Schuerffhobel. This is described as the usual German planes with the horn at the front. The cutting edge is said to be rounded while the sole is flat. They don't give sizes but remarkably, the next entry is the Schlichthobel for smoothing which is said to be larger! Because nowadays all German planes, except the jointer, are the same length, this is an indication that the Schuerffhobel was a smaller, especially narrower, plane with a heavilly cambered iron used for very rough work. A bit like the more modern German Schrupphobel.

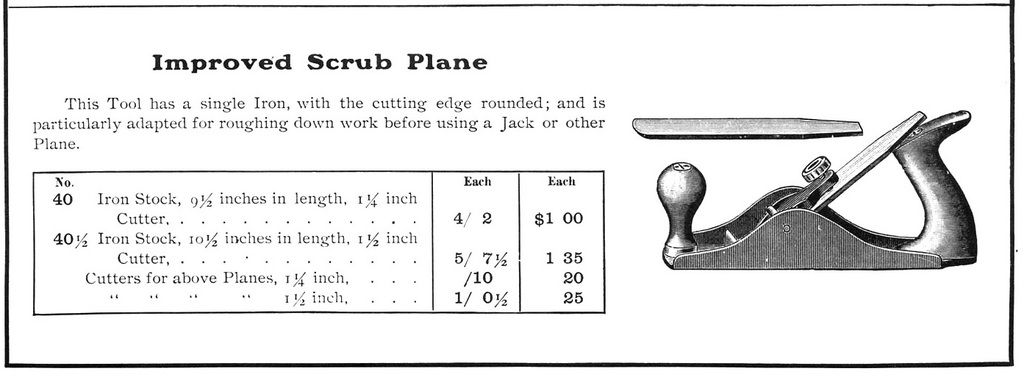

My Schrupphobel has the same size as a Stanley #40. 9 1/2" long with a 1 1/4" wide blade. It's made of wood of course and has the very convenient horn at the front. The very narrow width combined with the very agressive camber (radius about 3") make it a great little plane to remove wood in a hurry, across the grain. With the grain I don't really like it, it's much harder to push and tends to dig in all the time. The resultant surface is awfull. To get an idea, have a look at this older video from me, thicknessing a large wallnut board. Working like this across the grain looks like hard and sweaty work but it isn't that bad and it is very quick. At the end of the video you can see what it does to your board. As you can see the scallops are deep, and it is easy to go too deep, and damage more then you like, when only a moderate amount of wood needs to be removed.

In relatively modern times the German tool box contains these planes:

Schrupphobel for really agressive work, 32 mm wide iron.

Schlichthobel, wider (48 mm usually), single iron, usually used like an English jackplane

Doppelhobel or the Reform hobel, Both are smoothing planes, the latter has a 49 degree bedding angle. Both have a chipbreaker and have a 48 mm wide straight(ish) blade.

Raubank, The German jointer.

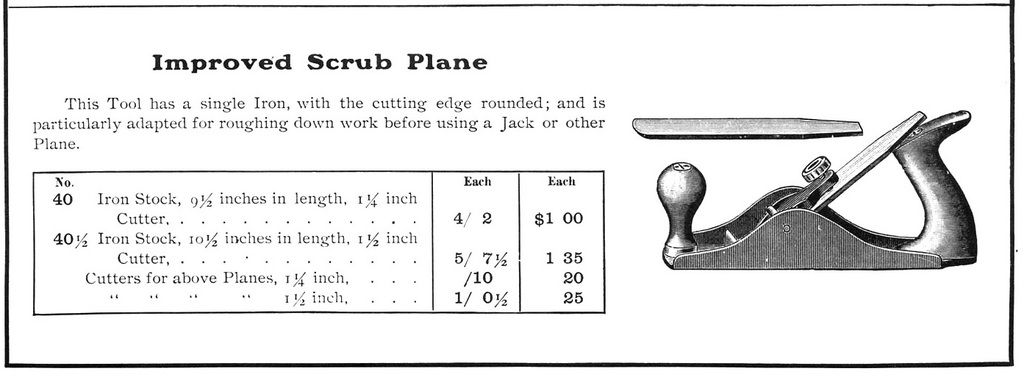

BTW, The Stanley #40 has almost the same dimensions as my Schrupphobel. Made of steel, so it is heavier of course. Single iron, 1 1/4"wide. I don't know how Stanley introduced this plane in 1896, but in the 1902 catalogue it is simply menioned as a scrubplane for rough work before using a jack or other plane. No mention about some specific trade or job. My idea is that is was introduced for the many German imigrants who could be pursuaded to trade their old wooden Schrupphobel for a real American made steel version!

Reply With Quote

Reply With Quote