So I have progressed my continual home renovation to the next project which are doors. I am looking for advise on how to construct the design below.

A few things to know:

1. This is my first attempt at interior doors.

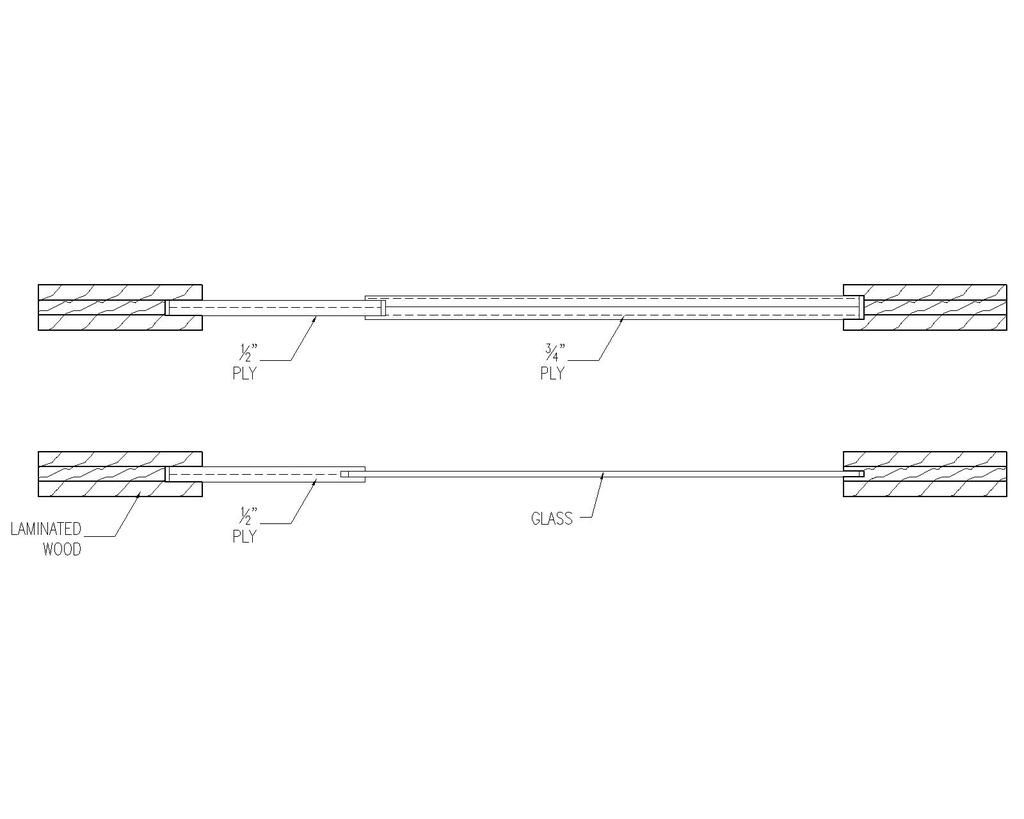

2. There will be various widths of doors and a few French doors as shown below.

3. Some will have 3/16" tempered glazing as noted in the design below, and others have either a 3/4" veneered mdf or plywood panel.

4. The curved part is a 1/2" or 3/8" (Walnut) veneered panel which would offset it from the 3/4" panel above and still allow for the glazing dado.

5. I planned on using dados for the glass and panels.

6. Considering building a jig to drill dowel holes in the stiles & rails, or a loose mortise & tenon which I am not really set up for.

7. Stiles & rails will be 3 layers of Kentucky coffee bean,cherry, or maple laminated and finished to 1-3/8" thick.

Please offer any suggestions, bad ideas, anything I am forgetting or have screwed up, elaboration on the above for me, as it would be greatly appreciated.

Jimmy

Interior Door Designs-Model.jpg

Reply With Quote

Reply With Quote

[/URL][/IMG]

[/URL][/IMG]