Brian,

I'm a huge fan of your work and really enjoy your website. I particularly admire how you use video to demonstrate your woodworking techniques in real time. For me, there is no substitute for actually watching a talented craftsman like you demonstrate how you build the beautiful furniture, and particularly the meticulous joinery, you do. I always look forward to your posts and read them eagerly.

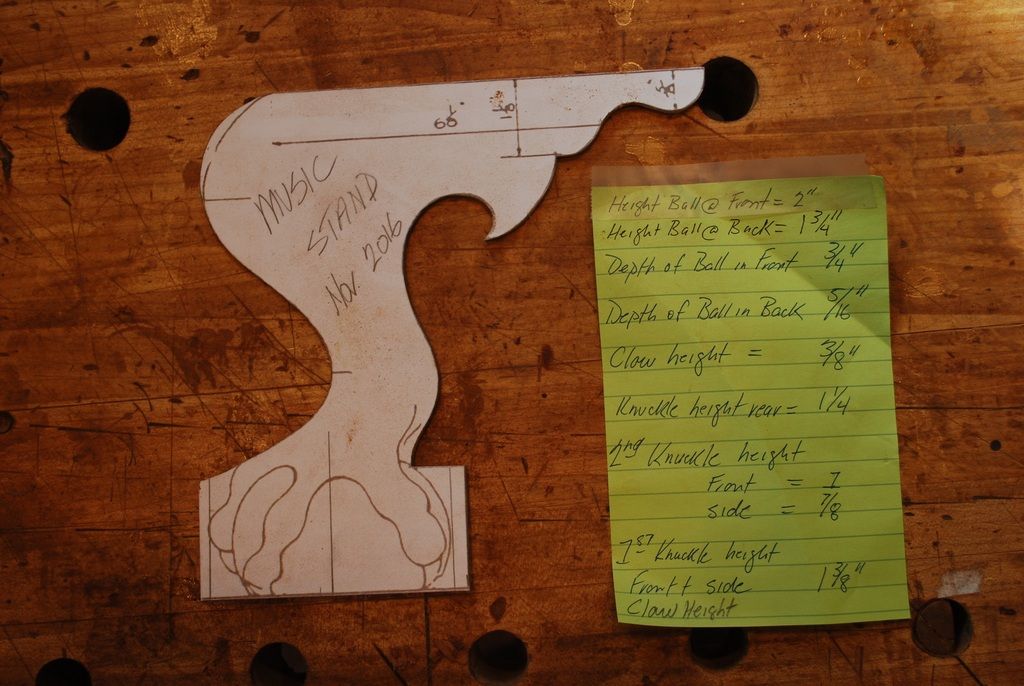

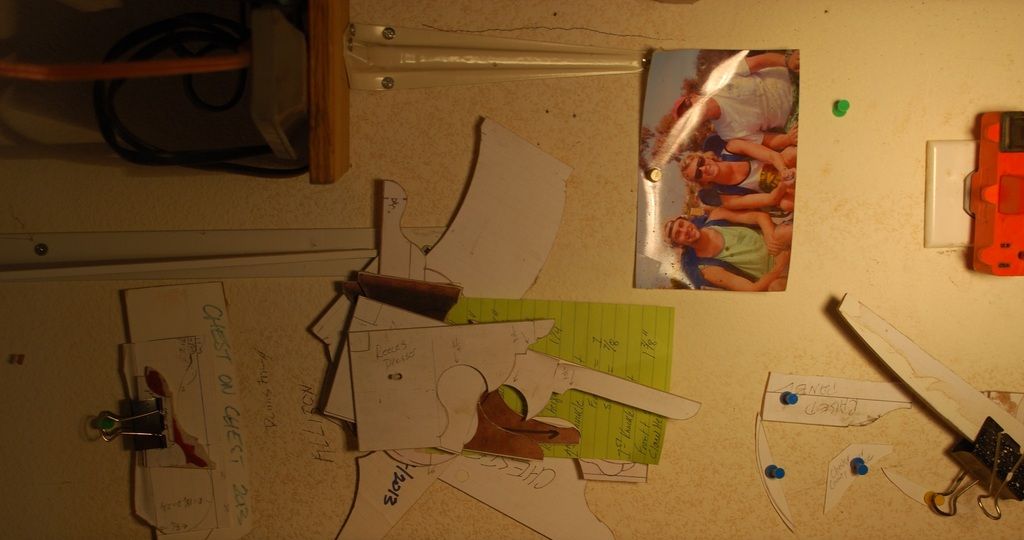

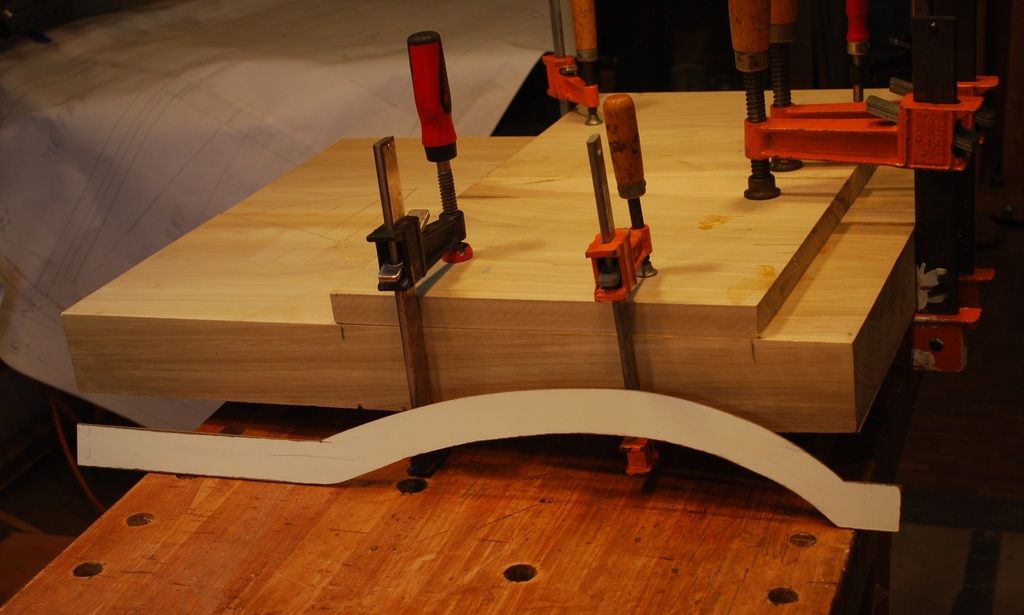

I am a IT luddite and surprised I'm able to post pics I hope are helpful.

All the best,

Reply With Quote

Reply With Quote

I'll never make them, but I do admire the way you are going about the, Mike. Keep going - I'm watching.

I'll never make them, but I do admire the way you are going about the, Mike. Keep going - I'm watching.