Hey all,

I'm still very early on in the learning curve and I have used some machines in the past (jointer/planer,ts, shaper) but now that I'm building out my own tools I don't want to spend the money on all those machines so I've been studying hand tools and have procured a few planes, chisels, and various other things. I've learned to sharpen them well (I think) but I struggle a little with time investment.

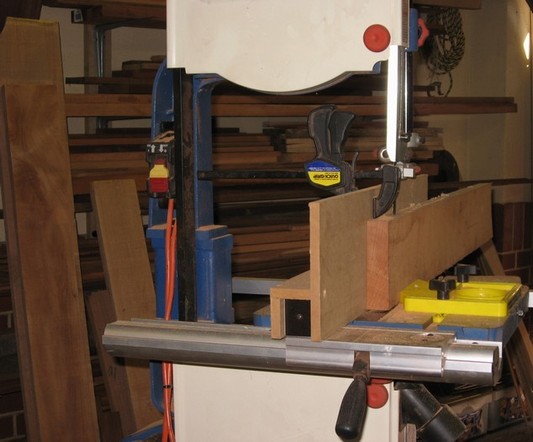

I was considering getting a planer at some point but the ones worth having seem to be really expensive so I've kind of gone back to the idea of milling stock with hand tools instead. I was reading somewhere about how one can use a bandsaw speed this process up quite a bit and then nudge it into perfection with a plane or two.

Could someone kindly explain how that would be done?

Reply With Quote

Reply With Quote