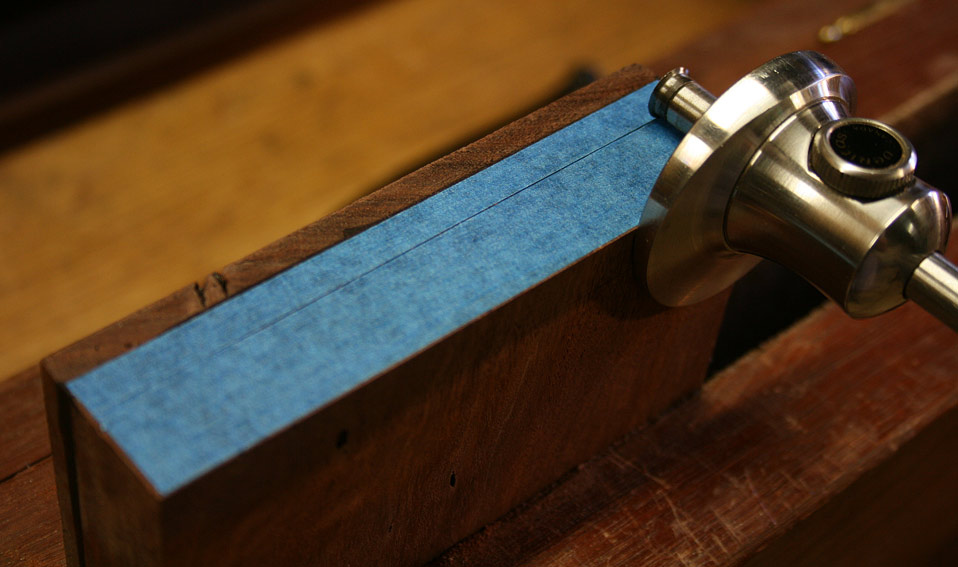

I dont know what i was thinking laying my pins dovetails out so that my pins would be so small. I started doing my layout and just went with it figuring it would be a good challenge.

So now the questions. I cut my tails first. I then marked my tails for the pins with a Blue Spuce marking knife.mi found it very very hard to reference the edge of my tails. At this point i already began to have concerns how acurate my pins would end up.

Well as expected they turned out a bit small in places.

So the question is when doing dovetails this tight that result in such a thin pin how do people accuately transfer their marks. I began to think that this may be a case where pins first makes sense?

Reply With Quote

Reply With Quote

That will give you plenty of practice...

That will give you plenty of practice...